As an importer, product quality affects your profit margins and the trajectory of your business. When you consistently produce high-quality products, your customers will remain satisfied. People will talk about your products on social media, recommend them to family and friends, and be loyal to your brand.

Over the years, we’ve shared many of our top tips to help you work effectively with suppliers and manage product quality. These insights have come in the form of articles, white papers, and downloadable guides. Our mission is to equip you with all the information you need to be great at quality management.

Below, we have compiled 10 of the most popular quality control articles on our site. We hope that having these resources in one place will be helpful to you.

Table of Contents

#1 What is AQL Sampling?

One way to ensure product quality is by conducting product inspections. AQL (Acceptance Quality Limit) is an international standard for inspection sampling defined as the ‘quality level that is worst tolerable’ during product inspections. If you are planning to conduct product inspections, it is vital to understand how AQL works. You can learn more about it in this article.

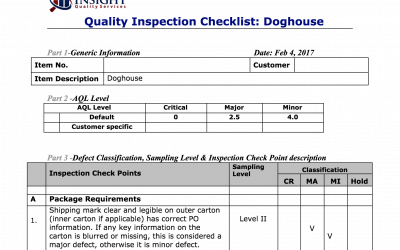

#2 How to Create Quality Inspection Checklists

Product inspections are a tool to help ensure that your products meet set quality standards. But how does the inspector know what to look for when they visit the factory? They are guided by an inspection checklist, which spells out all the tests and checks to perform. There are various factors to consider when coming up with an inspection checklist, outlined here.

#3 What is a Product Quality Inspection?

If you are a new importer, you may still be unsure of what a product inspection is or the different types of inspections you can conduct. Perhaps you’ve heard of factory audits and lab tests, and you wonder how they are all connected. This article defines quality inspections, discusses the types of inspections, and gives you a free guide on preparing for a product inspection.

#4 What is a First Article Inspection?

First article inspection (FAI) refers to inspecting several pieces of a product at the start of mass production. The purpose of an FAI is to ensure that your specifications are being met so you can avoid issues later on. This helps the factory reduce waste and prevents time-consuming and costly reworks. FAI is mainly conducted for high-precision products such as those used in motor vehicles or aerospace. You can learn more here.

#5 AQL Special Inspection Levels

AQL is an industry standard used in product inspections. The AQL chart tells inspectors how many samples to check and how many defects are deemed acceptable. The General inspection levels are used for most checks, but we use the Special levels for others. This can sometimes be confusing to importers, so we’ve explained it in this article.

#6 AQL Defect Classification

When conducting an inspection, the inspector determines whether the products are acceptable or not based on three types of defects. These are minor, major, and critical defects. In an AQL inspection, a specific number of defects is allowable in each category. Learn more about the three defect types here.

#7 Carton Drop Test

When you manufacture products overseas, they will generally be transported in master cartons. Whether the cartons are strong enough to withstand the rigors of international shipping can mean the difference between receiving quality products or broken pieces. As an importer, it is crucial that you verify your carton strength, which can be achieved by conducting carton drop tests. This article discusses carton drop tests in depth.

#8 Garment Quality Control Procedures

If you are in the garment industry, you know that consumers can be quite discerning when it comes to what they wear. As an importer, you want to ensure that you offer quality material and aesthetic appeal. Quality control for garments includes checking measurements, labels, and physical tests such as stretching and fabric tests. You can avoid importing poor-quality garments by understanding garment inspections, as outlined here.

#9 Mobile Phone Quality Check

The mobile phone has become a part of our lives, and we can’t seem to remember how life was before the hand-held gadgets. This makes quality crucial to the mobile phone industry. As a player in this industry, there are specific inspections that you need to be aware of and factors that you need to consider when coming up with an inspection checklist. They are outlined in this article.

#10 Inspection vs. Quality Control

As an importer, it is paramount that you understand the relationship between inspection and quality control. QC means putting verification processes in place to ensure that product quality is maintained throughout production. Inspection is one type of verification process involving testing and examining products to see if they meet your specifications. We discuss the relationship between inspection and QC here.

Download Your Free Price vs. Quality Guide

Importing goods from overseas makes sense for many importers due to the low costs of production. However, this doesn’t matter much if you receive low-quality goods that you can’t sell to your customers. It is essential to take all the necessary steps to balance price and quality. Our free Price vs. Quality Guide gives deeper insight into how to navigate these waters.

Please Note: This article was originally published in April of 2018 and updated in July of 2021.

0 Comments