China Inspection Services: How Smart Importers Avoid Costly Surprises

Table of Contents

You’re thousands of miles away from your manufacturer in China, and your goods are in production. You can’t see what’s happening on the factory floor, but your supplier assures you everything is completely fine and the products you ordered will absolutely meet your standards.

However, you worry that if there’s an issue they’re not catching, a quality lapse could wipe out months of your margins and affect your reputation in the market.

At Insight Quality, we work with many brands and retailers who’ve realized that they can avoid unexpected issues by establishing repeatable quality control procedures. Conducting professional product inspections helps them uncover hidden quality issues in China and protect them from costly, frustrating surprises.

Let’s discuss how they work.

The Cost of Skipping Inspections

Imagine you’ve waited six weeks for your products to cross the ocean on a container ship. It’s only after they arrive at your warehouse that you discover a major quality issue, such as missing components, incorrect assembly, or a color that doesn’t quite match your brand specifications.

Now, you either need to:

a) Rework your product at the warehouse, incurring high costs for local labor.

b) Ask your factory to remake and ship the order, which they won’t want to do for free and will take two months.

You could simply accept that some of your products are defective and sell them as-is, but that is likely to lead to chargebacks, return penalties, or retailer compliance failures. That’s generally not an option, so savvy importers conduct inspections before their goods leave the factory.

What’s the Real ROI of Third-Party Inspections?

Conducting third-party inspections in China can give you:

• Real visibility into the condition of your goods: A neutral inspector collects data about your products while they’re still at the supplier facility, helping you verify that they meet your standards.

• No need to fly someone overseas: Constant trips to China can be expensive, and having a local partner in the country can help you avoid travel costs, along with poor quality.

• An expert eye on your products: A trained QC professional can spot issues that buyers sometimes miss, such as subtle material substitutions that lead to creeping quality fade.

• Prevent seemingly small but expensive issues: Mistakes on your packaging can lead to chargebacks. Component swaps can lead to safety failures and recalls. Cosmetic defects can lead to returns and poor reviews.

• Keep your supplier accountable: When your factory knows you’re watching more closely, they are more likely to pay careful attention to details they might otherwise ignore.

• Build long-term consistency: Your customers will be happier when your products meet their expectations time and time again. You’ll give them fewer unpleasant surprises, resulting in smoother sales.

It can be tempting to skip inspections because they come with a cost, but in reality, you’re saving yourself from the expenses you’ll incur dealing with poor quality. Also, consistently meeting and exceeding your customers’ expectations will give you a competitive edge.

How Professional Inspections in China Actually Work

When you schedule an inspection, your products will not leave the factory until their quality is verified. After you book with Insight Quality Services, we send a trained local inspector to the manufacturing facility to evaluate the shipment on-site.

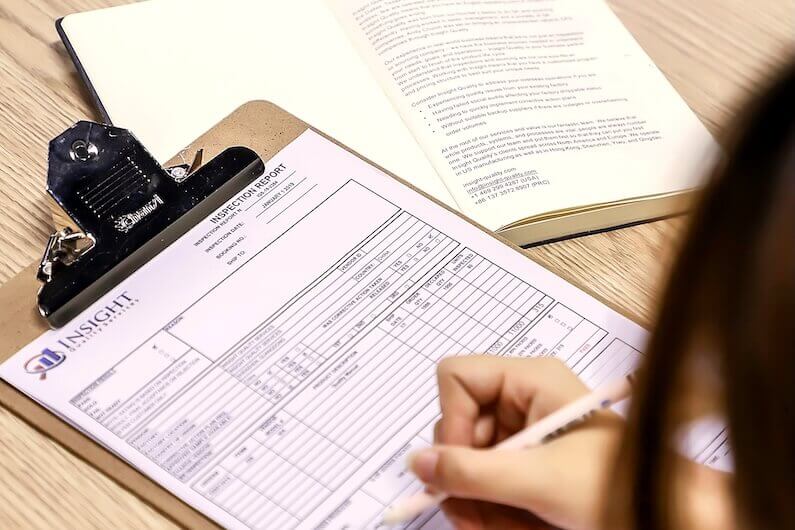

The inspector pulls random samples, reviews packaging and labeling, runs visual and functional checks, measures key components, and documents everything with photos and notes.

A typical inspection looks like this:

- Review purchase order & requirements

- Random sampling using AQL standards (industry-standard statistical sampling)

- Packaging & label checks

- Visual and functional testing

- Measurements & compliance checks

- Detailed reporting & pass/fail results

Beforehand, you share your requirements and any known risk areas, since no one knows your product better than you do. Then, as your inspection partner, we bring QC best practices and expertise.

Inspection Success Starts With a Clear Checklist

If you already have an inspection checklist, that’s great. We can use it. If not, we’ll create one together that’s tailored to your needs, ensuring the most essential quality points are verified every time.

After the inspection, you’ll receive a polished inspection report that includes the results, along with plenty of photos of your goods and any defects found. With this information in hand, you’ll be ready to either approve the shipment or request corrections from the factory while you still have leverage, since you haven’t made your final payment yet.

Professional inspections give you control, confidence, and a repeatable process to protect your brand for the long term.

Managing Defects Without Panic or Delays

Even with strong suppliers, you can expect quality mistakes at some point. The goal of inspections is not to avoid these mistakes entirely, but to catch them when they occur so you can address them quickly and professionally.

When defects are found, the process is simple:

- Review the inspection report

- Determine the severity of the defects

- Decide whether to rework, replace, or accept with a discount

- Confirm corrective actions

- Re-inspect if needed before shipment

Always schedule your inspections to happen before the final payment is released. This gives you leverage to ensure fast corrections if an issue arises. Once all results are satisfactory, you can make the final payment.

Set Expectations Early With Your Supplier

You should also set expectations with your manufacturer up front, letting them know that you will inspect. Come to an explicit agreement on who will pay for a reinspection if the goods fail. Getting the factory to agree to reinspection costs before production is a good motivator to ensure quality.

For critical or major defects, it’s likely that you’ll need to ask them to rework or remake the goods. When it comes to minor defects, you may be willing to accept the lot or negotiate a discount with your supplier.

Align with your supplier on a correction timeline and acceptance criteria before the rework starts. With everything documented in your inspection report, including photos of your products, you’ll be ready to have these discussions with confidence. You can resolve issues quickly and keep timelines on track without stress or surprises.

Why Importers Choose Insight Quality

When you’re managing production from thousands of miles away, you need more than inspections. You need a partner who takes the time to fully understand your product, speaks the same language as your factory, and protects your brand as if they were a part of your team.

Our clients often tell us we are an “extension of their team” or serve as their “China office,” helping them manage quality effectively without adding local headcount in China.

We’re a US-based company headquartered in Dallas, with operations in 32 countries. We coordinate our inspection network across China via our Asia operations base in Shenzhen, providing you with a responsive team on the ground.

We have conducted tens of thousands of inspections and have experience identifying a wide range of issues and helping clients to rectify them.

Whether you want to verify quality before goods ship, while they’re still in production, or even check the quality of your raw materials, our inspection services can help you catch issues early and ship with confidence.

Want to see how we work?

Download a sample inspection report or contact us today to discuss your needs.

Note: This article was originally posted on June 6, 2022, and has since been updated.

AQL Inspections 101: How They are Conducted

Authors

2 comments

Nitesh kumar

I want Haier inspection company

For metal import from china

Insight Team

Hi Nitesh,

For inspection inquiries, please email our team at info@insight-quality.com or fill out our Request a Quote form with more details.