AQL stands for ‘Acceptance Quality Limit,’ and it’s an essential sampling method used in quality control. It’s defined in ISO 2859-1 as “The quality level that is the worst tolerable” over the course of many inspections.

When an inspector goes to your manufacturer to conduct a product quality inspection, they use AQL sampling to answer two crucial questions:

- How many units should I inspect in a given shipment?

- How many defective products are allowable before the inspection fails?

When you import consumer products, it is vital to understand AQL so that you can work collaboratively with your inspectors. If you don’t understand the methodology fully, you risk misinterpreting your inspection results, which can lead to quality disasters.

Here we provide an overview of the AQL chart and how it works. You’ll learn how to use the AQL tables to answer the two questions above.

Table of Contents

The Acceptance Quality Limit (AQL) Chart

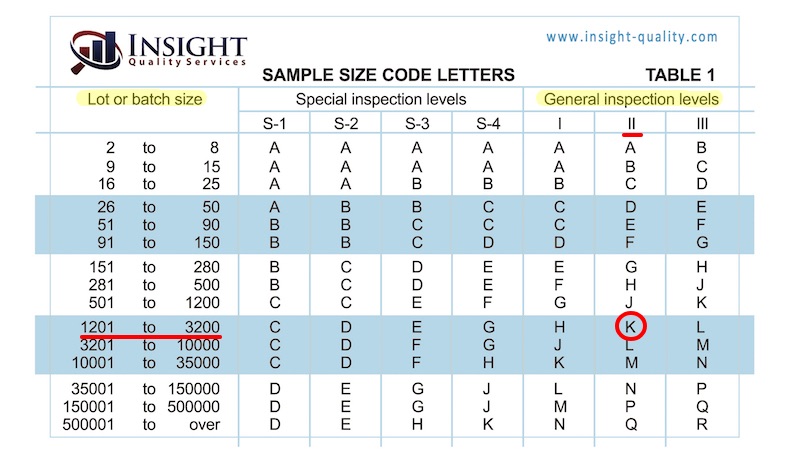

The AQL chart is made up of two tables, which you can see below. They are also often referred to as the ANSI/ASQ Z1.4 tables. And you can use them consecutively to arrive at your sample size and determine the number of allowable defects per lot.

These tables are based on the work of Harold F. Dodge and other statisticians who worked to improve them over the years. During World War II, Dodge worked at the Pentagon and developed quality control standards for inspecting US military equipment.

Today, importers use AQL to inspect all kinds of consumer products — from appliances to furniture to garments and more. In the next section, we’ll give a video overview of the chart and how to use it. Then, we’ll use reusable plastic cups as an example to help you understand how to use the tables.

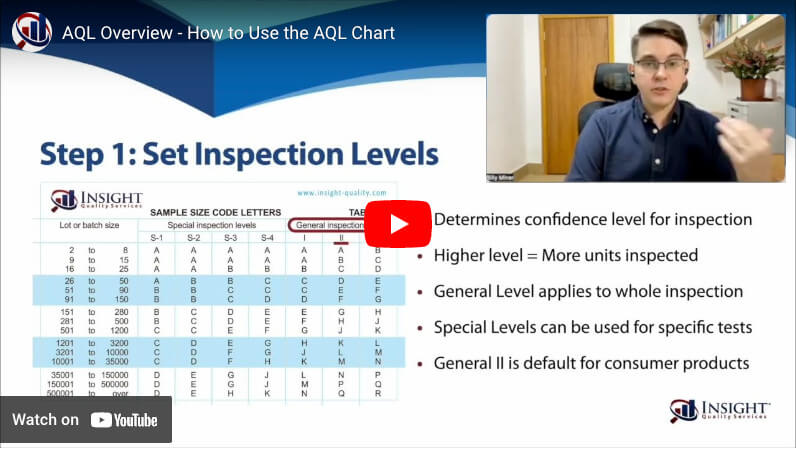

Video: What is AQL Sampling? + How to Use the Chart

In this video, we give you an overview of what AQL sampling is, what happens during an inspection, and how to use the AQL chart.

Below, we will walk you through an example of how to use the AQL tables to inspect an order of plastic cups.

Practical Example: How to Use AQL Sampling to Inspect Plastic Cups

Let’s say that you’ve placed an order with your factory for 1,500 reusable plastic cups. You’ve hired a third party product inspection company (like Insight Quality) to go to your factory before the order ships. You’ll use Table 1 to determine how many random samples they should pull.

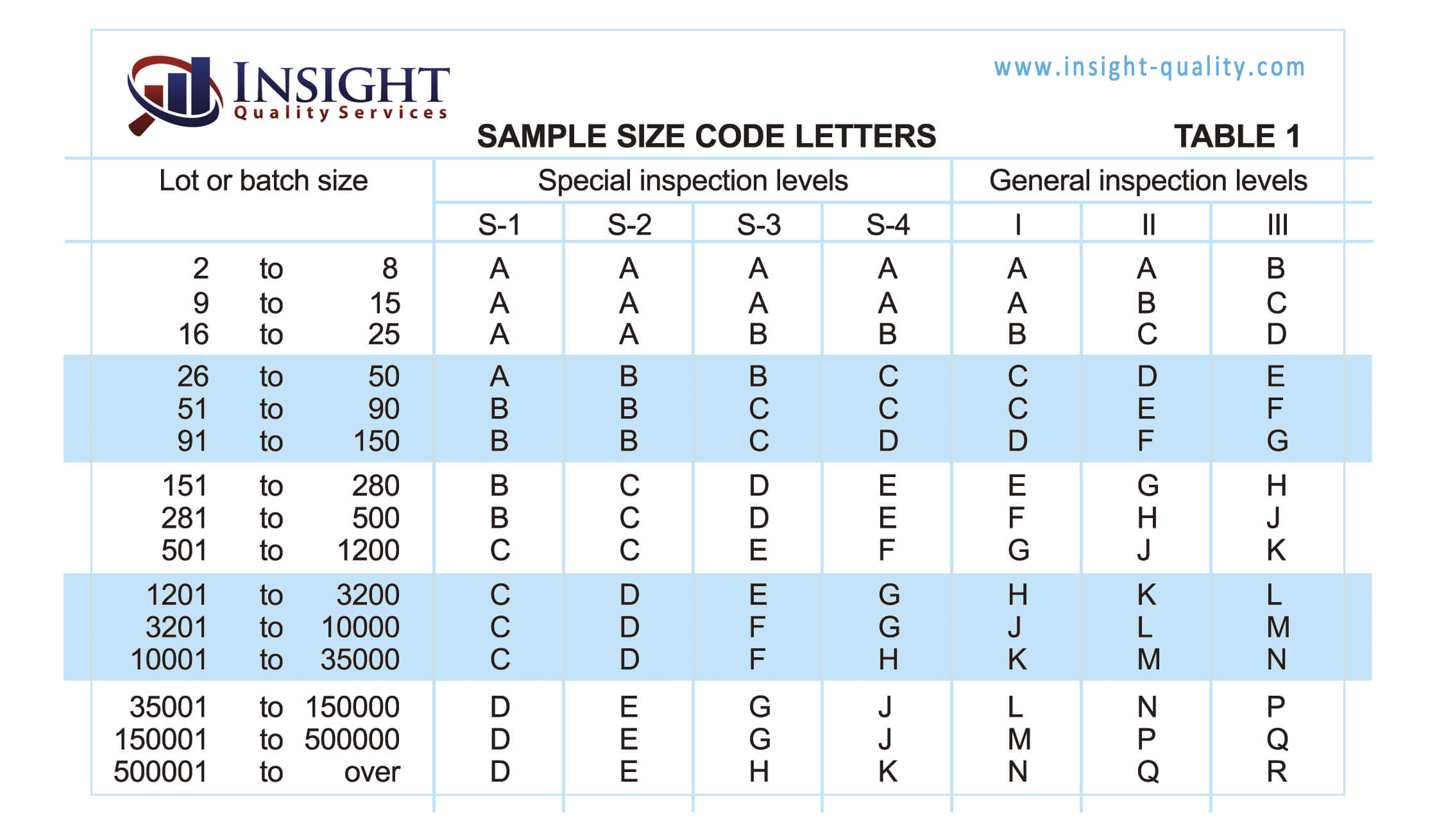

Table 1 – Sample Size Code Letters

Since your purchase order includes 1,500 cups, you can look at the ‘Lot or batch size’ column on the left side of Table 1 and select the appropriate range. In this case, the correct lot size is from ‘1201 to 3200,’ underlined in red.

Then, you’ll select your inspection level, which determines how many products the inspector should check. You can see that we have underlined ‘General Inspection Level II’ in red. As a rule of thumb, you can use General II for most consumer products. We will discuss the other levels in more detail later.

For now, look for the intersection of your ‘Lot or batch size’ row with the ‘General II’ inspection level column. You’ll see that your ‘Sample size code letter’ is “K,” which we’ve circled in red. We’ll use this code letter in the following table.

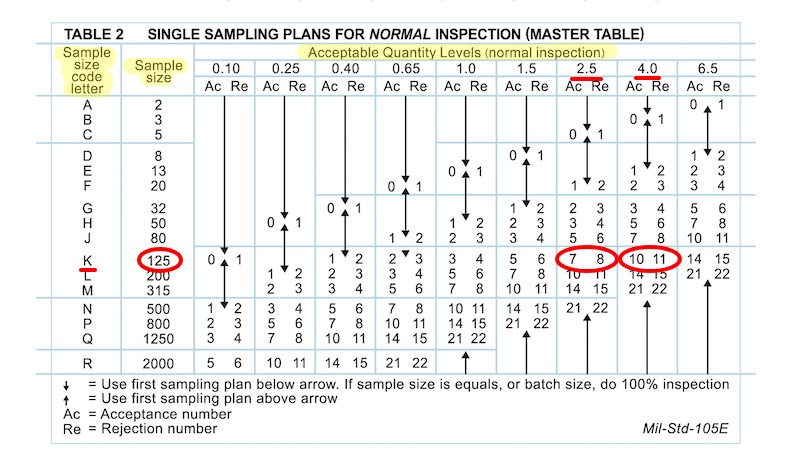

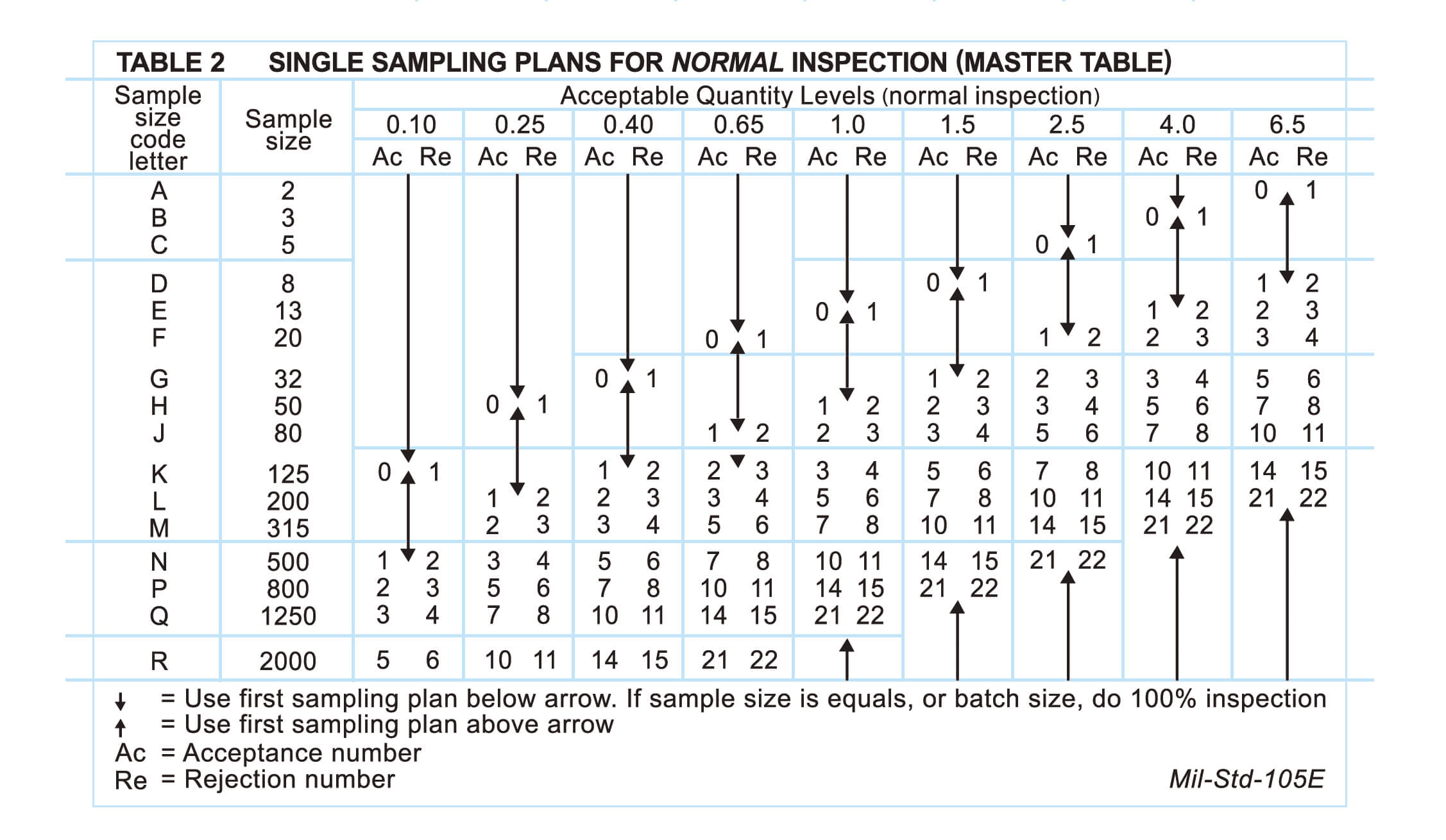

Table 2 – Single Sampling Plans for Normal Inspection

Now that we know your ‘Sample size code letter’ from Table 1 is ‘K,’ we will select it on the left side of Table 2. One column over, under ‘Sample size,’ we can see that the inspector will need to check 125 randomly selected cups from your shipment of 1,500.

To the right of the ‘Sample size,’ you’ll see various columns representing different Acceptable Quality Levels. For most general consumer products, the standard AQL levels are 2.5% for major defects, 4.0% for minor defects, and 0% for critical defects. That’s why we’ve underlined ‘2.5’ and ‘4.0’ above.

Going by this standard, we can see that your inspector will accept a maximum of:

- 7 major defects, and

- 10 minor defects.

A shipment with 8 major defects, 11 minor defects, or 1 critical defect will fail inspection. So your inspector now has the guidelines they need to make a pass or fail decision. If you’re unsure of the difference between major, minor and critical defects, read our article about AQL defect classification.

3 Things to Understand About the AQL and Inspection Levels

In our example above, we made certain assumptions. This first was that you would use General Inspection Level II in Table 1. The second was that you would use a 2.5% AQL level for major defects and a 4.0% level for minor defects. Below we will discuss some other alternatives.

#1 What are the General Inspection Levels? (Table 1)

There are three General Inspection Levels — I, II, and III. The level you choose is the main factor that determines how many units to inspect. In our example, we decided on Level II, which is the most common selection for general consumer products. Because of this, your sample size came out to 125 cups.

If you had chosen Level I instead, the inspector would check fewer cups, only looking at 50 of them. On the other hand, if you had chosen Level III, they would inspect more, in this case, 200 cups.

Why might you choose Level I or III?

Sometimes, inspecting fewer units (Level I) can reduce costs since the inspection takes less time. The downside is that you can have less confidence in the result. You should only conduct a Level I inspection if you have a long history and degree of trust with your supplier.

On the other hand, if you are working with a new factory or have had a spate of recent failures, you might opt to inspect additional units (Level III). An inspection with a larger sample size will take more time and effort to complete, thus costing more, but you can have more confidence in the results.

For more information, take a look at our article about the General Inspection Levels.

#2 What are the Special Inspection Levels? (Table 1)

There are four Special Inspection Levels — S-1, S-2, S-3, and S-4. Using the Special levels will give you a smaller sample size than any of the General levels do. For example, if you use Special Level S-1 on a 1,500-unit order, the inspector will only check 5 cups instead of the 125 from General Level II.

Why Would You Use the Special Inspection Levels?

The Special Inspection Levels do not generally apply to the entire inspection. Instead, they only apply to specific types of tests on your quality inspection checklist. For example, you might use General II to assess workmanship — checking for scratches, smudges, or cracks in the product, and you might use Special S-1 to check the dimensions of the outer carton.

Typically, you can use the Special Inspection Levels when:

- Testing is destructive to your product,

- Testing is very technical or time-consuming, or

- Certain defects are of low concern, and you need to move quickly.

For more information, take a look at our article about the Special Inspection Levels.

#3 What are the Various AQL Levels, Such as 1.0, 2.5, 4.0, etc.? (Table 2)

![]()

These different levels represent the AQL percentage you have chosen for your product. Keep in mind that they represent the maximum percentage of defects you are willing to tolerate over the course of many inspections.

The typical AQL levels for regular consumer products are:

- 2.5% for major defects

- 4.0% for minor defects

- 0% for critical defects

‘Major’ defects are those that will make your product unsaleable or lead to customer returns, while ‘Minor’ defects are only slight deviations from your specifications. ‘Critical’ defects are those that might pose a safety hazard to the consumer. For more information about major, minor, and critical defects, see our article on AQL defect classification.

5 Frequently Asked Questions About AQL

You may have one or more of the following questions.

#1 Why Use AQL Rather Than Inspect 100% of My Products?

You may think to yourself, “A 100% inspection would give me 100% certainty, so it must be the better choice.” And if you are purchasing low volumes, this is reasonable. However, full inspections become less feasible as your order quantities go up. The time to complete the inspection and its cost will increase.

AQL is a proven statistical model that has been used for decades. It has broad adoption across the quality control industry for a reason — it works. However, it’s important to remember that conducting an AQL inspection will not guarantee a defect-free inspection, as this is not its purpose. For more information, see Should You Conduct a 100% Inspection or an AQL Sampling Inspection?

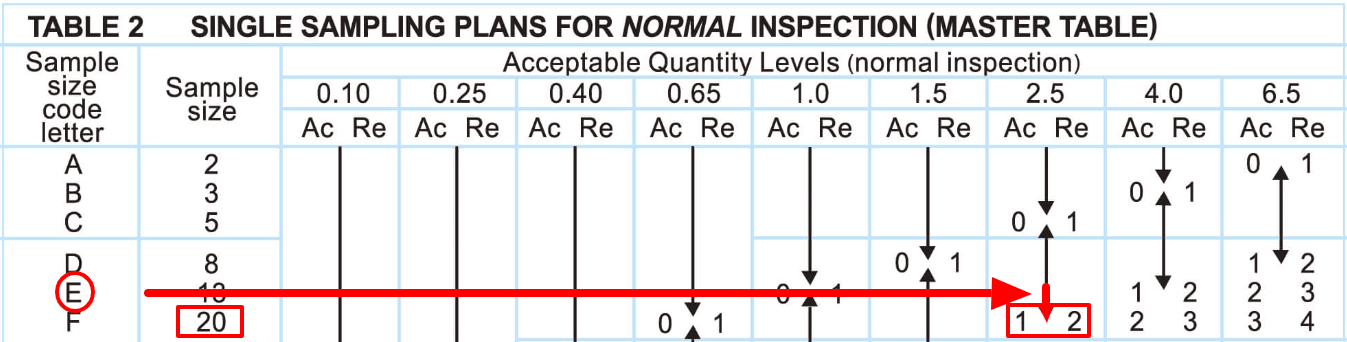

#2 What Happens When I Land on an Arrow in Table 2?

If the arrow points up, use the sampling plan above the arrow; if it points down, use the plan below the arrow. For example, let’s say you’ve ordered 90 sets of wireless headphones and decided on General II and 2.5% for major defects.

Your code letter is E, which lands you on a down arrow, so you move down to the lower sampling plan. You will inspect 20 sets, accepting the lot if there is 1 defect and rejecting it if there are 2 defects.

#3 Why Don’t the “Accept” Numbers Match My Selected Percentage?

Let’s say, for example, you have placed an order for 3,200 table and chair sets. You have selected General II and 2.5% for major defects — your code letter is K.

In this scenario, your sample size is 125, and you would accept 7 defects but reject the lot if there are 8 defects. 7 defects represent 5.6% of the 125 units you are inspecting, so why is this?

You should remember that AQL is a statistical tool and is probabilistic in nature. The 2.5% represents the expected long-term average defect rate over the course of many lots, not the percentage of defects in the sample size.

#4 How Many Cartons do You Pick the Samples From?

Let’s say you’ve ordered 1,000 units of your product and determined that you will inspect a sample size of 80. However, your goods are shipped in cartons of 10 units each, and you wonder how many cartons to pull samples from.

To determine this, the inspector always takes the square root of the total number of cartons plus one. Since there are 100 cartons, they pick 11 and then pull the samples from those.

#5 Does AQL Guarantee That My Shipment Will Have Zero Defects?

AQL is based on the quality levels you deem most appropriate for your product. In essence, it is not designed to ensure zero defects. It is generally unreasonable to expect zero defects outside high-risk industries like aerospace or pharmaceuticals.

However, AQL is flexible and allows you to set higher standards for your brand. For example, you could choose an AQL level of 1.0% for major defects instead of the standard 2.5%, making your standards more stringent. This type of adjustment might be appropriate for a high-end brand. For more information about this type of adjustment, see How to Choose the Right AQL and Inspection Levels.

Additionally, we recommend downloading the following guide if you want to be sure you have a firm grasp of AQL inspections.

Free Guide

AQL Inspections 101: How They are Conducted

- Get a solid grasp of the AQL sampling method

- Understand the AQL tables and how to use them

- Work with your third-party inspectors more effectively

Note: This article was originally posted in August of 2018 and updated in January of 2024

For AQL Level II, 2.5, 4.0, quantity is 2,500, sampling size is 125. Then major accept 7 = 7/125 = 5.6%, minor accept 10 = 10/125=8%. This is not 2.5% for major and not 4% for minor.

Please help to make me understand.

It is important to note the AQL does not equal the maximum percentage of defects that will be allowed in a sampling inspection. The AQL is the highest proportion defective that is considered acceptable as a long-run average for the process. Therefore a lot inspected to a 2.5% AQL may be passed by a Z1.4 sampling plan even if its true proportion defective is 5.0% or higher for majors; 4.0% AQL for minors can have a true proportion defect rate of of 8.0% or higher.

Aql major 1.5, minor 4.0, lot size 80, how many pcs of sample size

The sample size is determined by the lot size and chosen inspection level. The sample size on a lot size of 80 could be 3, 5, 13 or 20 depending on the inspection level.

Can you judge acceptable quality level in school quality assurance

Products made for use in school such as calculators, notebooks, backpacks are consumer products that would be inspected the same as other general consumer products.

Good day,

For AQL Level II 0.25,

(1) Lot size 501 ~ 1200, is it sampling size 80, Ac 0 and Re 1,

(2) Lot size 1201 ~ 3200, is it sampling size 125, Ac 1 and Re 2?

Please help me to understand if I’m wrong. Thank you.

Actually, for your two examples, you would use:

(1) Sample size: 50, Ac 0 and Re 1

(2) Sample size: 200, Ac 1 and Re 2

For the first one, the arrow on the chart points up, so you move to the above sampling plan. For the second one, the arrow points down, so you move to the lower sampling plan.

Maybe 3 comments to help users on this topic:

– approximate definition of AQL value is “the percentage of defects in a batch where sample inspection has approximately 90-95% of chances to pass”. This means:

. AQL is probabilistic. It i the key for proper understanding. 2 AQL on the same batch could provide 2 different results

. AQL value measure a risk for the supplier, not a risk for the customer

. even though a batch contains a quantity of defect equals to AQL value, there is still 5-10% to reject it

. batches having a quantity of defect far above the AQL value still have a significant probability to be accepted. With a sampling plan K and AQL 2.5%, a batch containing 6% of defects still have 50% of chance to be accepted.

– It should reminded to users that putting an AQL of 0.00% e.g. for critical defects is absolutely meaningless unless to perform 100% inspection of the batch. There is a common confusion between “critical defects” with the most stringent AQL and expected zero defects in a sample, and “redhibitory” defects where 0 defects is expected in full batch. Zero defect in a sample does not mean zero defect in a batch!

– AQL is by design weak to perform quality control for release at a batch level due to its probabilistic nature, and should be more considered as strong tool to monitor consistency of a process overtime with consecutive AQLs on consecutives batches. More than a tool providing “magic answers” to release batches, AQL is somehow more designed to perform risk management on defects.

HTH.

Thank you for sharing some thoughts. It is certainly true that zero defects found doesn’t mean a defect free batch. While AQL sampling inspections are not perfect, AQL sampling inspections are a proven methodology and a tool to provide buyers with a level of confidence that their order meets their quality expectations.

If your individual units come in shippers (say 10 units per shipper), how do you determine how many shippers to choose from?

To determine the number of cartons to select the sample size from, we take the square root of the total number of cartons and add 1.

https://insight-quality.com/quality-basics-frequently-asked-questions/

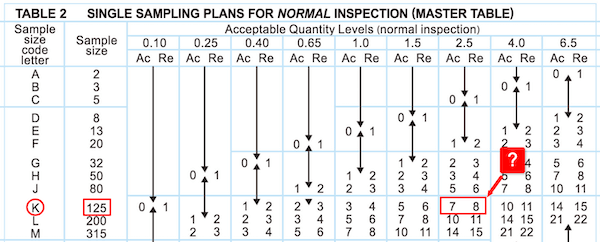

Sir, Very useful and I have used your notes for explaining the AQL /Sampling scheme to ERP end users. Here my doubt is , in second table for ‘K’ = 125 units, if my AQL is 0.25% what is my Ac& Re, since it is showing Arrow marks instead of value. Which arrow mark ( upper or lower ) considerable?. As per my knowledge it may Ac1 & Re2 .Please correct me sir.

You can refer to the notes on the bottom of the chart. If there is a down arrow, use the first sampling plan below the arrow; for an up arrow use the first sampling plan above the arrow. In your example of .25 AQL the accept = 1; reject = 2

https://insight-quality.com/resources/aql-chart/

Wouldn’t your sample size also need to be increased to 200 since you have to drop down to the next level?

That is correct, Michael. Sample size should be increased to 200.

According to AQL, could you please tell, how to precise the number of measuring samples per size for a textile inspection?

Is there any standard or its determined by customers?

The determination of what inspection level to use is up to you. Generally for measurements we suggest using a special level, S2 for example.

Hello Insight,

For measurements on textile products, say a shirt, would this AQL be applicable? This AQL z1.4 is for attributes, so if one measure is out of tolerance, does it become an attribute? Wouldnt using sampling by variance be more relevant? Z1.9 ?

Hi Insight, in response to your response to Theja’s comment above, should the sample size not move to 200 also?

Yes, the sample size should be adjusted to use the first sampling plan below the arrow. If the sample size is equal to or more than the batch size then 100% inspection should be conducted.

Question regarding “acc” – “rej” in Table 2-A of the ISO 2859. We have 100 parts to be machined in 4 lots of 25 pcs. The requirement is AQL is 1.5. Our Insp. level is II, our code letter is “C” and our sample size is “5”.

How do I interpret the “0” under the “acc” column. We’re only given one AQL and that is the 1.5.

Does “0” mean no defects allowed”?

OR

Does is “acc” column interpreted to mean major” defect?

In your example of a lot/batch size of 25 and AQL 1.5 the sample size would be 8 because you would use the first sampling plan below the arrow. Accept 0/Reject 1 means 0 defects are allowed. The accept/reject numbers are not defined by major/minor defect classification and no assumption should be made as to whether it is major or minor defect.

Thank you for the explanations. What about an importer who verifies the correct composition of certain products purchased piecemeal? Does “a lot” only concern one arrival? Or can it represent the whole of a reference purchased over a year? Is there a Special inspection to prefer instead of general II ?

A lot is a quantity of goods submitted for an inspection and which the sample size is drawn. An inspection would be conducted on a lot and the results would only apply to the lot submitted for an inspection. If there are numerous lots/shipments over a year the results of one inspected lot would not apply to another lot. The use of different inspection levels such as Special Level 1 (S-1) or a General Level 2 (GLII) is dependent on client situations but we generally recommend conducting a General Level 2 while certain function or special tests may be conducted using a smaller lot utilizing a Special Inspection Level.

Great discussion. It has long been a concern of mine, that people use the AQL plan as some kind of magic solution.

Thank you Insight, for framing this correctly, that it is not ‘one size fits all’. It really begs on Quality managers to hire QE’s who understand STATISTICS, and who know how to applie the proper methods to each situation.

Instead, the ‘John Cheap-hire Doe Mfg.’ Company thinks they can save money by hiring lower paid inspector, and handing them an AQL CARD for sample sizes.

SERIOUSLY?

What is even more crazy, is that CB ISO auditors rarely know this key information either!!

From my studies, it appears that AOQL, average outgoing quality level, is a much more valuable metric to the real output of your plant or factory. But again, AOQL requires an engineer who knows STATS, and can apply them in practice, at reasonable costs.

Thank you guys and gals!!

Thank you for your kind words.

If a critical defect has an AQL of 0%, how do you apply this using the Sampling Tables. Since there is no AQL of 0%, are the Sampling Tables not applicable in this case? Does this imply that a 100% inspection be performed?

Additionally, how do you track the General Inspection Level for the same part made by two different suppliers? For example, Supplier 1 has a good history of producing acceptable cups. Supplier 2 has a poor history of producing acceptable cups. It would not be fair to Supplier 1 to move the inspection to an increased sample size because of Supplier 2’s defects. So, how do you relate a supplier to the General Inspection Level?

Hi Nate,

For critical defects, there is no need to use the sampling table. If one product has a critical defect, the inspection is failed.

It does not imply that a 100% inspection is performed, as AQL is still probabilistic. And it is generally only in higher-risk/higher-value industries where 100% inspection is performed, e.g. aerospace. If an airplane part has a critical defect, that is likely more serious than a critical defect on a ceramic mug.

Regarding the General Levels, you can use different levels for different suppliers. For example, you could use General I for Supplier 1 in your example and General III for Supplier 2. Or you could move to skip-lot inspections with Supplier 1 and inspect less frequently while increasing your inspections at Supplier 2.

Hi, at the end of my production process, I have 100% general function test, then we do destructive test with AQL system. In this case, how should I determine my sample number?

Let’s say I produce 250 products, but only 150 passes the general function test. In this case, the number of sample is determine based on the 250? or 150? thank you

Hi Inge,

The purpose of a Final Random/Pre-Shipment Inspection is to verify the quality of goods that have already been produced and packaged. So, it might depend on whether you consider the general function test to be part of a Pre-Shipment Inspection vs. part of in-line QC.

When it comes down to it, you could do it either way. But it sounds like after they finish the general function test, you would want to package the goods and conduct a separate AQL inspection on the completed 150.

You most likely used the 250/150 example for simplicity, but if there really were that many products failing the general function test, you might want to try inspecting goods much earlier in the process. That way, you could focus on working with the factory to determine what is going wrong and improve the manufacturing process.

Buen día.

Tengo una pregunta:

– Matemáticamente por que se se saca la Raíz cuadrada a un lote de cajas; las cuales contienen varios artículos.

Saludos

Este método es una norma industrial fiable que se utiliza desde hace muchas décadas. No tiene necesariamente una base matemática, sino que se utiliza como forma de obtener un buen número de cajas para seleccionar al azar, sin abrirlas todas.

Hello –

When pulling samples of a product for inspection, how would you suggest handling the following scenario? I have a delivery of parts arriving and the lot size is 100,000. I am checking these parts for 2 different attributes. One attribute requires a sample size of 50 parts, and another attribute requires a sample size of 200 parts. What is your recommended approach?

1. Pull a sample of 50 parts and inspect for attribute #1 on those 50 parts only. Pull a second sample of 200 parts and inspect for attribute #2 on those parts only. Total samples pulled = 250

2. Pull a sample of 200 parts and inspect the first 50 parts for attributes 1 and 2. Then inspect the remaining 150 parts for attribute 2 only. Total samples pulled = 200

3. Pull a sample of 200 parts and inspect all 200 for attributes 1 and 2. Total samples pulled = 200.

4. Other?

Thank you so much for any insight you can offer!

Hello Brian,

Whether to pull one sample or two depends on many factors. For example, the decision might be affected by a limited number of man-days to conduct the inspection or the factory not wanting to repackage additional units after inspection. In these cases, you might lean toward a single sample to save time pulling and repackaging the units.

It also might depend on the types of attributes you want to check. For example, if you were checking a mobile phone and wanted to verify that it charges, you would need to plug in some units and set them aside while checking other attributes on separate units.

In many cases, you can check multiple attributes on the same unit. For example, if attribute #1 was a height x width x length measurement and attribute #2 was a particular Pantone color, you could likely use the same units.

Hope this helps!

Hello Insight, how can AQL be adapted for food manufacturing raw materials?

Thank you for your comment. Fruit and food raw material quality control are outside our scope of business. However, we believe AQL is not typically used for this purpose. It would be best to consult with a company that provides services in this area.

Hi, if my customer is using AQL 1.0, what AQL level should I be using?

The decision to use a particular AQL level generally comes down to the specifics of your product and market. See this article regarding how to choose AQL levels. We suggest having a discussion with your customer regarding their expectations to aid you in this decision.

what are the standards for sampling of pesticide product

Hello Humza,

Unfortunately, pesticides are outside the scope of the products we inspect, as we are generally focused on consumer products. For more information about relevant sampling standards, we suggest reaching out to a company that does quality control for these substances.