How Do Container Loading Inspections Work, and Do You Need One?

Table of Contents

Do you want to minimize the risk of carton tampering during container loading? Are you ordering multiple containers of goods and using container stuffing plans to maximize efficiency? Or have you established packing and marking systems to minimize product damage?

If you answered yes to any of these questions, a container loading inspection might benefit you.

A container loading inspection helps ensure that a supplier loads the right products in the right quantities and follows your loading plans. An inspector supervises the loading process and verifies that all packaging materials, labels, and barcodes meet your specifications.

How do these inspections work, and how do you decide if you need one? Let’s discuss that in more detail.

How are Container Loading Inspections Conducted?

Once the factory finishes production and packages all the goods in your purchase order, they need to load them into a container for overseas shipping. You can supervise this process by sending an internal inspector or utilizing third-party loading inspection services.

You might inspect at a factory, warehouse, or port, depending on your unique situation. While there, the inspector verifies that the master carton and pallet labeling match your requirements and that the container meets your needs.

The loading supervision may include the following checks:

- Packing and marking status

- Loading process

- Condition of the shipping container

- Loading documents review

The inspector verifies that the supplier performs all loading and transportation processes as expected. They ensure that everything goes smoothly and that workers handle everything appropriately. This helps protect the goods, ensuring they survive the overseas journey in good condition and there are no unpleasant surprises at arrival.

Is a Loading Inspection Necessary for Your Situation?

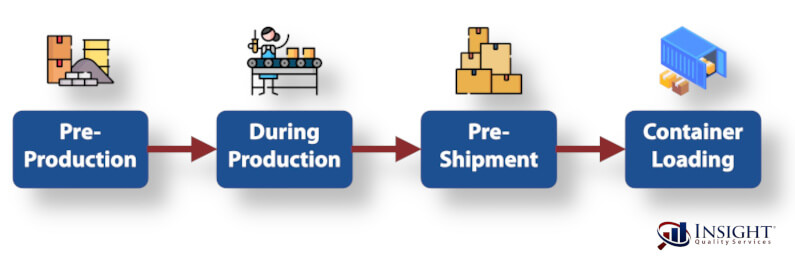

There are several types of inspections that you can conduct to verify the quality of your products at various production stages. These include pre-production, during-production, and pre-shipment inspection.

While these other inspection types help ensure the quality of your goods, they don’t account for the loading process. Things can quickly go wrong if mishandling occurs during loading.

Sending an internal inspector or hiring a loading inspection service like Insight Quality will help you verify the following:

- The container meets your needs and is properly sealed

- The quantity and type of products loaded match your purchase order

- All labeling and barcodes match your specifications

- Cartons are loaded carefully handled and safely loaded

- Workers follow your loading plans precisely as laid out

Here are a couple of scenarios that might require a container loading inspection:

- You produce expensive, fragile products such as crystal vases, delicate artwork, or glass cabinets. Shipping these products requires that anyone handling them uses extreme care and loads them appropriately into the container.

- You have developed a container stuffing plan to fill your containers more cost-efficiently. Perhaps you’ve used free or paid container stuffing software to specify the exact positioning of all your cartons, and the individuals loading your container need to follow this process strictly.

A loading inspection is appropriate for any situation in which you want to supervise the loading of goods into the shipping container.

Incorporating Container Loading Inspections into Your Plans

Consider a container loading inspection to verify what your supplier is loading into the shipping container and how they do it. Many companies that order full containers of goods consider these another tool in their supply chain management toolkit.

They often have a robust quality control plan that includes various types of inspections, such as pre-shipment, during production, pre-production, and loading inspections, by using all these tools at different times.

Contact us if you have further questions about conducting container loading inspections in China, Vietnam, or elsewhere around the globe. We can help you assess if container loading inspections fit your supply chain needs.

Additionally, we recommend the following guide if you’d like to learn more about working with a third-party inspection company.

AQL Inspections 101: How They are Conducted

Authors