Pre-Shipment Inspections in China: 5 Things You Need to Know

Table of Contents

Are you working with a manufacturer in China? Are you far away from the factory but thinking about sending someone to make sure the goods meet your quality standards? Many importers in this situation choose to conduct pre-shipment inspections.

A Pre-Shipment Inspection (or PSI) is a quality check that occurs once your goods are 100% produced and at least 80% packaged. An inspector goes to the factory in China, pulls a random sample of products, and runs through a checklist to identify defects before the order ships.

At Insight Quality Services, we’ve conducted thousands of Pre-Shipment Inspections in China to help buyers verify quality. Here we explain what you need to know about the service.

What are the Steps in a Pre-Shipment Inspection?

This is our basic procedure for conducting a pre-shipment inspection. It is also sometimes called a final random inspection:

- Go to the Factory: An inspector meets with factory staff to get acclimated and set up. They pull a random sample of products from your order using a method called AQL.

- Conduct Pre-Shipment Inspection: The inspector runs through an inspection checklist and verifies that the goods comply with your quality standards. They visually check to ensure they meet all physical requirements. They assess functionality and ensure they are correctly packaged and labeled for shipping. Check out our sample QC checklist if you want to learn how to create your own.

- Finalize Inspection Report: The inspector writes a report to summarize their findings. It shows the results of all the quality control checks, including photos of the goods and any defects found. It gives a pass, fail, or hold result, so you can choose to accept or reject the shipment. Download our sample inspection report to see what it includes.

Why are Pre-Shipment Inspections Important?

Pre-shipment inspections help ensure that the products coming from the factory match your specifications, are up to your quality standards, and are packaged and labeled correctly. They help you avoid costly quality defects and shipping issues.

Remember that if you don’t discover defects until after your order ships, it’s probably too late to do anything about it at that point. Inspecting before you make your final payment to the supplier lets you hold them accountable.

5 Things You Need to Know About Pre-Shipment Inspections in China

1. How to Hire the Right Inspection Agency

Hiring the right third-party inspection agency for your company is critical. When deciding who to work with, you should consider a variety of factors, such as whether they are fully certified to provide inspections in China with an ASQIQ license.

They should also be experienced in your product category whether it’s furniture, textiles, electronics, building materials, or something else. Try asking for references, about their coverage area, and whether travel expenses are included in the cost.

Of course we’re biased, but we think we do a great job, so feel free to contact us for a quote for your China Pre-Shipment Inspection!

2. How to Develop an Inspection Checklist

The quickest way to conduct an unhelpful inspection is by not setting clear expectations beforehand. You should be incredibly detailed in laying out what you want the inspector to check for. Your inspection checklist should be well thought out and touch on packaging, labeling, visual inspection, functional testing, and more.

If a particular type of defect is not accounted for in your checklist, the inspector will not necessarily look for it. So it is essential to work with your inspection company to develop this list.

3. How to Establish which Party is Responsible for Re-inspection

What happens if your inspector discovers excessive errors during the inspection and the lot fails? In that case, the manufacturer will need to rework your products. Once they do, you’ll have to verify that they are now satisfactory by conducting another inspection. But who pays for it?

In your contract with the supplier, you should include a stipulation that if goods need to be reworked, the factory is responsible for re-inspection. This way, they have an added incentive to get it right the first time, and you don’t end up with additional costs to ensure they’re doing their job.

4. How AQL Sampling Works in Quality Control

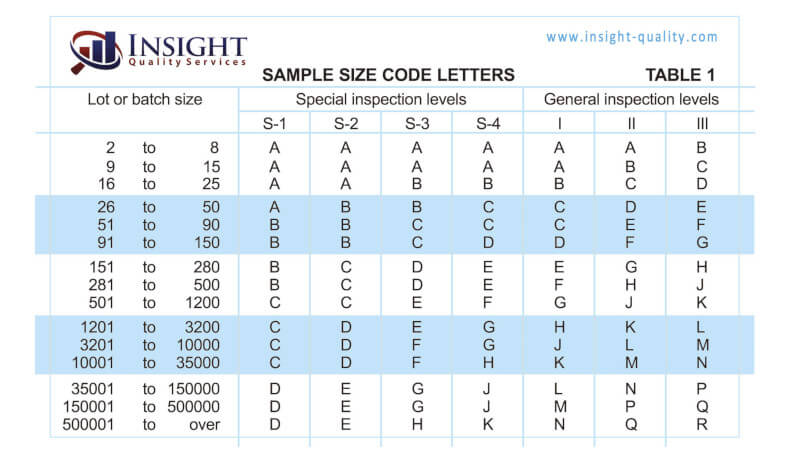

When your inspector goes to the factory in China, they will need to pull a random selection of products to check. But how do they choose these products? To do this, they use a method called AQL, or Acceptance Quality Limit.

This sampling method is vital because it determines two key things: 1) how many units to inspect, and 2) how many defective products are allowable before the goods fail inspection. Before conducting your inspection, it is essential that you understand this method and make the right selections. To learn more about this, you can read our article on AQL sampling or download our free guide to using it.

5. How to Keep Improving Your Results

When your products are subject to a PSI, you’ll receive an additional benefit: the comprehensive inspection report. Even if everything is up to your current quality standards, this report will contain insights about your current shipment and clues as to what may need improvement.

For example, your PSI may reveal some minor defects. Even if you accept a minorly defective shipment, you can take action to communicate the discrepancy to your manufacturer so they can fix the error or test different materials and/or processes in your next batch.

To see what the inspection report looks like, download our sample inspection report.

Insight Quality Services Can Help You Ship Great Products

Insight Quality Services is an ASQIQ-certified company that offers top-notch Pre-Shipment Inspection services in China and worldwide.

Contact us to request a quote or download our free guide on successfully preparing for a product inspection, below.

Are you thinking of hiring a third-party inspection company? If so, you need to be properly prepared. No one knows your product better than you do. So, make sure you give your service provider the information they need to ensure that your inspections are a success.

Download this free guide to successfully preparing for your product inspections.

AQL Inspections 101: How They are Conducted

Authors

6 comments

Jan Geisshirt

Hello.

We will be placing POes by 3 different suppliers of Stainless-steel profiles and fittings in grade 1.4404

So, I need to find an inspection company, which have an PMI tester / alloy tester, do you have one ???

Insight Team

Thank you for your inquiry. I have forwarded it to our inspection team at info@insight-quality.com.

Naved Ahmed

My manufacturer in China, making 500 pieces for me for backpack. I need quality checking before shipment how much do you charge? Let me know please thanks.

Insight Team

Hello Naved,

Please visit our Request a Quote page and fill out the form to get a price estimate for your inspection. Or you can email info@insight-quality.com.

Raju Kutty

Hi,

Do you have experience in doing PSI for Steel Wire Rope in China?

What is your charge?

Do you have any office in Dubai?

Insight Team

Hi Raju,

Thank you for your questions. For service inquiries, please email info@insight-quality.com, and we will be happy to assist you.

Comments are closed.