Your products need to meet quality standards, legal requirements, and customer expectations. However, when you import products from overseas, verifying that your manufacturer consistently meets these requirements becomes difficult.

If you don’t have an on-site presence at the factory, it helps to have someone who can do quality control on your behalf. This is where third-party inspections come in.

What is a third-party inspection, and what benefits does it offer? How do you decide between third-party and in-house inspections? We’ll answer these questions in this article.

Table of Contents

What is a Third-Party Inspection?

A third-party inspection is an assessment of your goods for quality control purposes. As the name suggests, it is not carried out by the factory or the buyer. Instead, an independent third party (like Insight Quality) conducts it at the factory.

Our clients typically send us to the factory once their supplier finishes a production run for a pre-shipment inspection. However, we sometimes inspect goods during production or even check raw materials before it starts.

Inspections typically involve visual inspection, packaging and labeling checks, functional testing, verification of physical requirements, and other steps. To learn more, read our article about the types of inspections.

Why Not Rely on Your Manufacturer’s QC Department?

Reputable factories should have quality control measures in place, and although they may have professionally trained employees, their quality control (QC) staff is always accountable to factory management. As such, the QC department’s interests may not fully align with yours.

If you have an office near the manufacturer and the resources to send one of your employees to inspect, that’s great! However, many companies do not or are short-staffed, so they hire a third party like us to act on their behalf.

When you hire a third-party inspector, they are not accountable to factory management. They are also professionally trained and proficient in sampling methodologies, such as Acceptance Quality Limit (AQL) sampling.

What are the Benefits of Conducting a Third-Party Inspection?

Some of the benefits of conducting a third-party inspection are:

Impartial Inspectors

Since a third-party inspector is not affiliated with the factory or your company, they will give an impartial, independent report. As such, you are more likely to get an accurate picture of your goods on the ground.

Qualified Inspectors

Third-party inspection agencies have the right qualifications, training, and experience in product inspection. Many third-party inspection companies like ours specialize in particular product categories, which means we understand what to look for during the inspection process. Our inspectors may also work faster and more efficiently, finishing the required inspection within a set period.

Cost-Effective

Unless your order volumes are high enough to justify a permanent presence near the factory, hiring an inspection company can help lower your costs. Inspectors can travel to the supplier’s facility at any point in the production process, and you will only pay based on the “man-days” spent.

Increased Sales & Customer Satisfaction

Having your order inspected while it is still at the factory helps ensure that you receive quality goods. If you supply consistently high-quality goods, consumers are more likely to become loyal to your brand. As such, they may refer your products to friends and family and write about your brand on social media, leading to improved business outcomes.

In-House vs. Third-Party Quality Inspectors

When deciding between your in-house quality inspection team and a third-party service, it ultimately depends on your priorities: what you want to do in-house versus what you want to subcontract.

Some importers choose in-house teams to save money, but this comes with additional costs, such as salaries, transportation, and the management required to supervise and train the inspectors. Without proper training and oversight, the costs can add up.

However, third-party inspection companies give you the following.

Scalability

They offer scalability, especially during peak seasons, without requiring a full-time inspector. A local third-party inspector might also be more cost-effective than flying someone from abroad. Moreover, outsourcing QC inspections helps avoid bias by rotating inspectors to maintain objectivity and good relationships with the factory.

Expertise

Third-party inspectors can be beneficial when you need additional expertise for specific products or to verify the performance of internal inspectors. Many companies specialize in technical expertise that may surpass the capabilities of your in-house team.

Cost

Using a third-party service also allows you to avoid the additional costs of hiring full-time inspectors, including salaries, social insurance, and housing. This makes third-party inspections more flexible, as you can scale the service up or down based on your needs.

Having a reliable partner can save time and money when issues arise. To achieve the best long-term results, consider what’s most important for your business.

Third-Party Product Inspections: Insight Quality Services Can Help

As we discussed above, there are numerous advantages to having your goods inspected by a third-party inspection service. At Insight Quality Services, we’ve completed tens of thousands of inspections in China and across 18 countries.

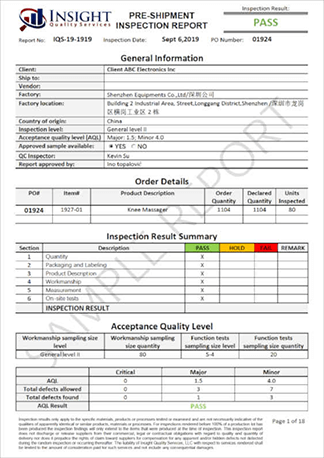

If you want to know more about how we can help you conduct inspections at your factory, contact us today. Below, you can download a sample report to help you better understand what a third-party inspection report contains.

Download a Sample Inspection Report

Each time a product inspection is completed, we send you a report with the inspector’s findings. This inspection report gives you key information about the condition of the lot inspected.

It shows the results of each check performed and includes a collection of photos taken by the inspector. The photos allow you to see the condition of the products and packaging exactly as they looked during the inspection.

Note: This article was first published in March of 2020 and updated in February 2025.

Hi. Thanks for this article. The question is that “When” the inspection is being done? Suppose the inspection done prior to the days of shipment, boxes are labelled, checked. But what if exporter do not load that particular cargos, of change the inside material?

The benefit will only be there, if the inspection do the inspection on the day of the loading of the cargo, & mention the Container Number in the inspection report.

Otherwise, who knows goods checked on monday are being exported on thursday or not!

Please reply.

Thanks

Pre-Shipment Inspections should take place when production is 100% complete and at least 80% packed.

We generally recommend that pre-shipment inspections take place 2-3 days prior to the ship date from the factory as this allows time to remediate any observations from the inspection that require attention or reworking.

However, if there is a concern that the goods might not be loaded correctly or if there is a customized container loading schematic, you can conduct a Container Loading Inspection to reduce the risk of products being swapped at loading.

Hi Insight Team,

I appreciate this informative article, it provided me with a lot of valuable information. I am in alliance with different third parties. Suppliers are aware that third-party inspections can be performed on the 80%-packed quantity, and often choose not to package their 100% shipments. Suppliers may intentionally leave defective goods un-packaged, and only pack the remaining quantity after the PSI process. We attempted to select samples from the unpacked 20% quantity, but accurately identifying whether the samples are 20% is challenging due to the product’s dispersed distribution. When we share the packed figures with the inspection company they allow us to continue the inspection. But later on in some cases there is a contradiction for defects ratio between the report and actual received delivery.

Could you please share your thoughts on it?

Thanks

Hello,

Here are some thoughts on this situation.

1. Identify and assess the quality system of factory. When working with a high-risk factory, refuse to conduct the inspection unless 100% of goods are packed.

2. Have the factory put the products into holders/trays/cartons with labels equally distributed by a batch time of 2 hours. The inspector can draw samples equally from different time periods by this method.

3. It is essential for the factory and customer to collaborate and communicate well. Smooth communication between the customer, inspection company, and factory is key to resolving these issues.