Can you prove where your raw materials are coming from?

This question is no longer optional if you’re importing silicon or cotton-based products from China. It’s at the heart of compliance with the Uyghur Forced Labor Prevention Act (UFLPA), and getting it wrong could mean seized shipments, hefty fines, and serious reputational damage.

At Insight Quality Services, we’ve been helping companies navigate this complex landscape through traceability audits—deep-dive investigations that map your supply chain all the way back to the source. Recently, I sat down with our founder, Andy Church, to discuss why these audits have become essential and how they’re helping importers stay compliant.

Read on to learn more, or watch the full discussion on YouTube.

Table of Contents

The New Reality: When Supplier Capability Verification Isn’t Enough

The compliance landscape has fundamentally shifted. “It used to be that verifying a factory was capable of making the products that you were buying was enough,” Andy explains. “Now traceability is vitally important because just verifying your factory can do what they say they can do is just one element of due diligence.”

This change isn’t happening in isolation. Three major forces are driving the demand for supply chain transparency:

1) Regulatory Compliance: The UFLPA in the US and various regulations in the EU have made traceability a legal requirement, not just a nice-to-have.

2) Consumer Demand: Today’s consumers expect transparency. Many can now scan QR codes on food products and apparel to see exactly where ingredients were harvested or cotton was grown.

3) Risk Management: Companies are realizing that visibility into their supply chain protects them from quality issues, recalls, and compliance violations.

What Traceability Audits Actually Look For

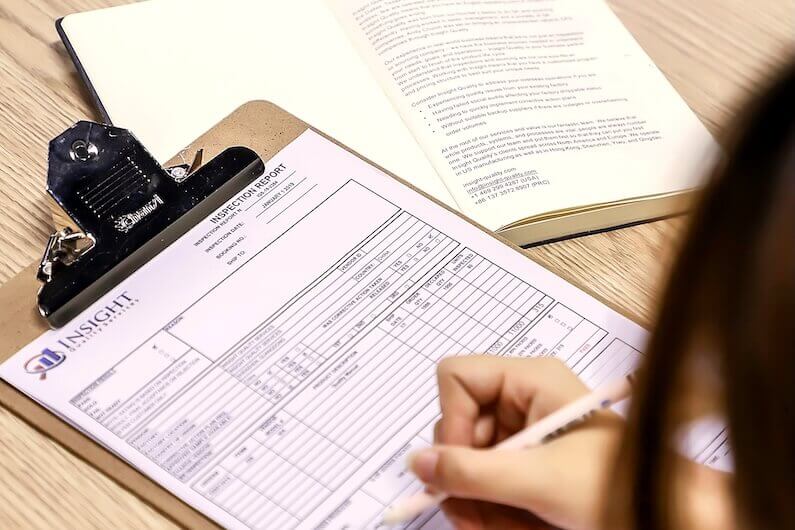

When our auditors conduct traceability audits, they’re doing detective work that goes far beyond paperwork review. Here’s what they examine:

Documentation Deep Dive

- Bills of materials and bills of lading for all incoming raw materials

- Invoice verification and supplier documentation

- Proper record-keeping systems and processes

Process Verification

- Whether factories have their own supplier audit programs

- Systems for verifying incoming materials

- Due diligence procedures for vetting suppliers

Red Flag Investigation

“The auditors are looking for discrepancies,” Andy notes. “When incoming raw materials into the warehouse don’t have a corresponding bill of lading or invoice, the auditors research that and discuss with the proper personnel at the factories.”

The Cooperation Challenge: Getting Suppliers On Board

One of the biggest hurdles in traceability audits isn’t technical—it’s human. Suppliers often resist these audits for several reasons:

1) Lack of Understanding: Many suppliers simply don’t grasp why traceability matters or what the audit process involves.

2) Resistance to Change: “This is the way I’ve always done it. Why do I have to have this documentation now?” is a common refrain.

3) Fear of Exposure: Some suppliers worry about what auditors might discover.

4) Resource Constraints: Factories may lack the expertise or personnel to properly support audit activities.

However, Andy emphasizes that cooperation is becoming more common: “Many factories are excited about the improved efficiency and reduction in risk that traceability audits can provide them. The factories who are doing the right things are excited for these audits because they build trust and stronger partnerships with their clients.”

How Deep Should You Go? From Silicone Suppliers to Quartz Mines

One of the most challenging questions companies face is determining how far upstream their traceability efforts should extend. The answer isn’t simple.

“How far upstream is enough is going to depend on the industry of our client and the raw materials or components that go into their product,” Andy explains. The complexity varies dramatically by product:

- Simple Supply Chains (like imported shrimp 🦐): Farm → Packaging → Import

- Medium Complexity (like tomato paste 🍅): Grower → Processing facility → Import

- Complex Supply Chains (like apparel 👕): Cotton farm → Cotton mill → Dyeing → Manufacturing → Import

For UFLPA compliance, the answer often reaches back to the very beginning. “For compliance with regulatory issues that deal with labor, it’s going to be all the way back to the farm or the mine,” Andy notes. This is why at Insight we have found ourselves auditing actual quartz mines—all the way upstream from the silicone suppliers one of our client purchases from.

Getting Started: Your First Steps Toward Traceability

If you haven’t conducted traceability audits before, Andy recommends starting with an internal exercise:

The SKU Test: Pull a product from your warehouse or distribution center. Can you determine when it was made, by which factory, and from which supplier? Can you trace it back to the original purchase order?

“This is often a step that is conducted in a recall exercise,” Andy explains. “If you can do that, that’s a great first step—you already have some of the systems in place.”

Before jumping into full traceability audits, consider starting with quality and systems-based audits to ensure your suppliers have the basic capabilities for traceability. “If they don’t, jumping right into a traceability audit would be a wasted effort.”

The Bottom Line: Traceability Is Here to Stay

The days of hoping regulatory scrutiny will ease up are over. “This isn’t something that is going to go away,” Andy emphasizes. “Over time, traceability audits and due diligence of suppliers are going to increase.”

For companies importing silicon-based products, cotton goods, or other high-risk materials from China, traceability audits aren’t just about compliance—they’re about protecting your business, your reputation, and your relationships with customers who increasingly demand transparency.

The question isn’t whether you need to implement traceability measures. The question is whether you’ll be proactive about it or wait until a compliance issue forces your hand.

How Insight Can Help You

Ready to get started with traceability audits?

At Insight Quality Services, we help companies navigate complex supply chain compliance requirements with confidence. Contact us to learn how we can help protect your business and ensure your supply chain meets the highest standards of transparency and compliance.

You can also download our free guide to general factory audits below.

Free Guide

How to Prepare for a Factory Audit

A factory audit helps you assess a supplier's systems, capacity, workplace environment, or capabilities to ensure they meet your requirements as a buyer.

But which type of audit should you conduct, and which points should you cover on your checklist? In this free guide, you'll learn how to run an effective supplier assessment.

0 Comments