It’s a trap many consumer product importers fall into: the belief that third-party inspection is a magic bullet to fix their quality issues. They think inspecting their products is the single key to making high-quality goods that earn rave reviews. But, alas, this is a narrow view that overlooks the bigger picture.

As the renowned 20th-century quality guru W. Edwards Deming aptly puts it in his book, Out of the Crisis, “Inspection does not improve the quality, nor guarantee quality. Inspection is too late. The quality, good or bad, is already in the product. As Harold F. Dodge said, ‘You can not inspect quality into a product.’

As a third-party inspection company, we want to clarify the role of inspection in the quality management process. Inspection is not a solution to quality issues but rather a tool to identify them. It helps you understand the state of your production output, but it alone cannot improve the output. It’s like a thermometer that detects a fever but doesn’t treat the underlying illness or prevent it from recurring.

So, what are the keys to product quality?

Table of Contents

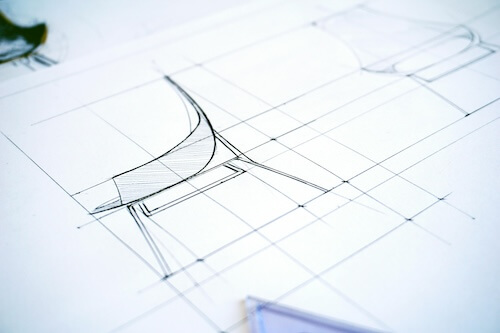

The Role of Design + Clear Specifications

Inspecting helps you verify whether goods from the factory meet your standards, but the real question is, how good are your standards? This is where design and specifications come in. They are the foundation for high-quality products. A well-designed product with clear specifications is more likely to meet your quality standards, making the inspection process more effective.

Design

Your products must be designed with the right materials, dimensions, finishing, and other attributes to give your consumers the best possible experience. For instance, if you’re selling a kitchen appliance, the choice of materials can affect its durability and safety. The dimensions and finishing can impact its functionality and aesthetics. These are all factors that can influence your product’s quality.

If you’re concerned about how long your product will last before it wears out, you must ask yourself questions such as, “Which materials do I choose to ensure a long lifespan?” If you want to keep it looking nice throughout its life, you might ask yourself, “Which surface finish is the most appropriate?”

If you do not design your own products but have them designed by the factory, getting familiar with your product inside and out is vital. Understanding the materials, construction, finishing, and manufacturing process as thoroughly as possible not only makes you more knowledgeable but also helps you compare your product with competing ones and identify any potential issues.

If you inspect your product and it is coming off the production line precisely as designed, it might pass inspection. However, if the design is flawed to begin with, inspecting will not improve the product’s quality.

Specifications

In China and other developing countries, there’s a phenomenon known as ‘quality fade.’ It’s like a slow, silent killer of product quality. The factory makes minor changes to your product over time, which may seem insignificant at first. But, over a year or more, they can add up and lead to major quality issues that can harm your business. It’s important to be aware of this phenomenon and take steps to prevent it.

Quality fade is not always malicious—it can stem from a lack of definite requirements, along with shrinking margins caused by rising costs and pressure to keep prices low. This is why it’s essential to create and maintain a detailed specification sheet. By doing so, you are taking proactive steps to ensure product quality and maintaining control over the manufacturing process.

A specification sheet is a crucial document that outlines all the requirements for your product. It should include detailed information about the materials used, the components and their specifications, the measurements and tolerances, the packaging details, and any other requirements for your product. Once your supplier has agreed to these specifications, you should include the sheet as an addendum to each purchase order.

Detailed specifications help guard against quality fade because they give the factory a clear standard to meet and leave little wiggle room for changes. The more well-thought-out your standard is, the more effective your inspections will be because you can verify adherence to it.

The Manufacturing Process

Assuming you have a well-designed product with clear specifications, the question becomes, “Is your manufacturing process capable of reliably turning out these products one after the other?” When relying on outsourced manufacturing, this means you need to fully understand your supplier’s capacity and capabilities.

Assessing Your Suppliers

Can your supplier reliably and repeatedly make your products meet the standard you’ve set? Do they have the quality systems in place to ensure consistent output? If they are underperforming, are they willing and able to make improvements?

Conducting factory audits is critical to ensuring a manufacturer can meet your standards. These assessments allow you to evaluate the manufacturer’s capabilities, quality systems, and workplace environment.

If you have high standards for your product, these assessments are crucial, as they can help you identify potential issues before they affect its quality. Factory audits can be used as a last step when qualifying a new supplier or as a tool for ongoing supplier management.

Sometimes, the supplier relationship can start off on the right foot, but quality deteriorates over time. Ongoing assessments allow you to look for changes occurring at your supplier’s facility and work with them to improve. This can often be more effective than scrapping them and looking for a new supplier.

Remember, inspecting after production will only tell you something is wrong—it won’t be able to fix the situation. Choosing the right manufacturer and working with them collaboratively on supplier development will help ensure you get the results you want.

What is The Role of Inspections?

As ASQ states, inspection is a “verification activity” that can involve “measuring, examining, testing and gauging one or more characteristics of a product or service.” Assuming that you have precise specifications that identify all the attributes the product should have, you can engage in inspection to verify the product’s attributes match.

Ideally, an inspection should confirm that everything is turning out as expected — assuming you’ve taken all the other steps, such as designing the product well, specifying its attributes, and assessing the supplier. However, if an issue does come up, you can identify it and then look into finding a solution. You can work with the manufacturer to take the necessary steps to prevent it from happening again.

Just remember, quality doesn’t come from the inspection process. Quality comes from designing, specifying, and conducting supplier assessments. Then, inspection allows you to monitor the results of the production process to ensure you’re on track.

Insight Quality Helps You Assess Suppliers and Inspect Products

We offer inspection services to help you verify production output, factory audit services to help you assess suppliers, and lab testing services to ensure regulatory compliance. If you want to ensure product quality and need assistance, contact us. Our reliable inspectors worldwide can travel to your supplier to help you keep your quality program is on track.

Note: This article was originally posted in October 2020 and updated in June 2024

Isn’t quality inspection necessary to gather data on the reoccurring defects? This leads to initiating a search into what part of the manufacturing process is causing the defect and then the process can be improved. Wouldn’t that save money that would have been lost on returns and scrap?

It is definitely beneficial to use data from inspections to address recurring issues so the cause can be identified and addressed. Focusing on supplier development and working together to find solutions with your factory will save the costs associated with reworking or scrapping poor quality product.