Blog > Product Inspections

Read & Explore New Stuff

Product Inspections, Quality Control

Pre-Shipment Inspections in China: 5 Things You Need to Know

AQL, Product Inspections, Quality Control

How to Choose the Right AQL and Inspection Levels for Your Product

AQL, Product Inspections, Quality Control, Video

How to Use the AQL Inspection Levels (General & Special)

Product Inspections, Quality Control

How do Pre-Shipment Inspections Work? An Overview for Importers

Product Inspections, Quality Control, Video

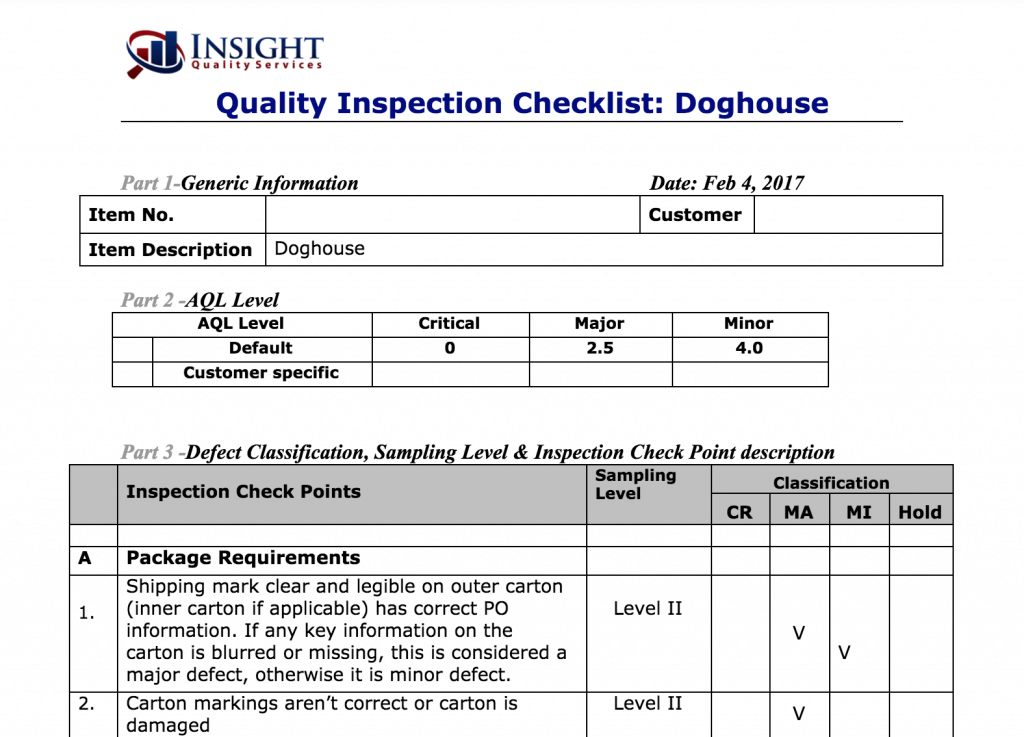

Quality Inspection Checklists: How to Create Them

Product Inspections

What is a DUPRO Inspection, and Why Would You Need to Conduct One?