Quality Inspection Checklists: How to Create Them

Table of Contents

When you sell consumer products in the US or European market, working with manufacturers in low-cost countries can be fear-inducing. The possibility that you might randomly receive a shipment of substandard or unsafe products is like an ever-present shadow looming overhead.

It often makes sense to put your own quality control measures into place, which leads many importers to conduct product inspections at the factory. Whether someone on your team conducts these inspections or you hire a third-party QC company (like Insight Quality) to help you, it is essential to have an effective quality control inspection checklist.

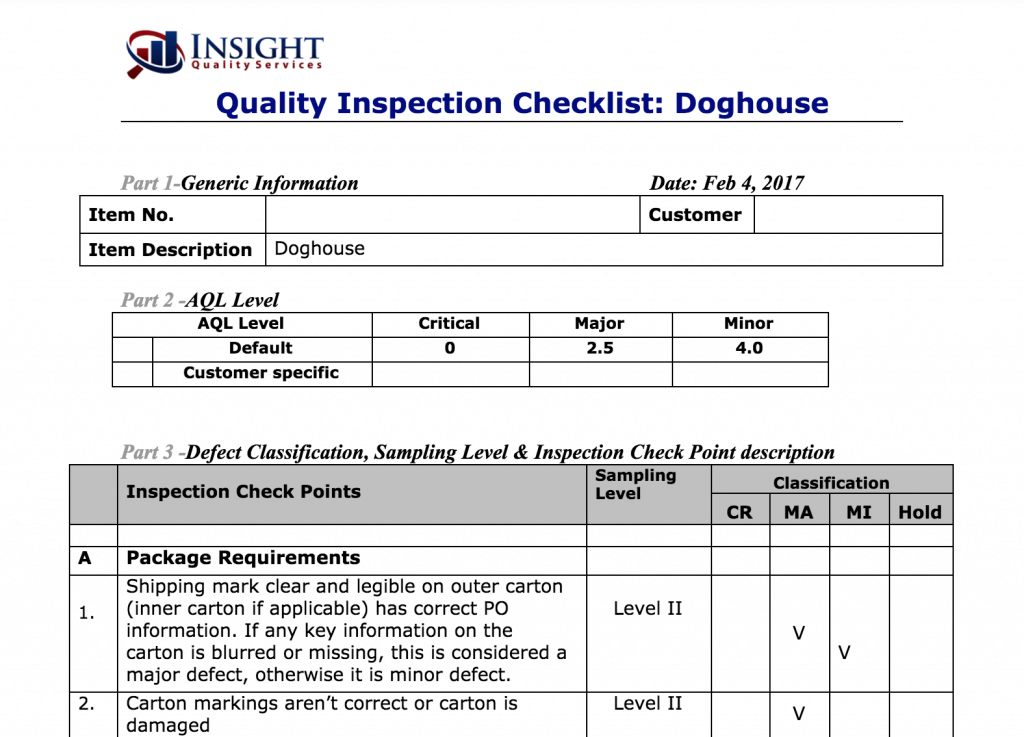

This video and article talk about what a QC checklist is and how to create and organize one. You can download a free inspection checklist template below, which provides guidelines for inspecting a doghouse. Use this template to help you generate ideas for your checklist.

What is a Quality Inspection Checklist?

An inspection checklist serves as a guide for the person inspecting your products during a product quality inspection. Whether you go to the factory yourself to check the quality of your products or hire a third-party QC company to do so, the checklist tells the inspector what to look for.

A well-thought-out checklist gives you or the inspection service provider clear criteria to follow when checking your products. It also gives your manufacturer a set of specific standards to meet, and the increased accountability makes them more likely to produce goods that meet your expectations.

How do you go about creating your quality control checklist?

Step 1: Think About the Defects That Might Occur During Manufacturing and Create a Defect List

Different types of products are prone to different defects. For example, if you’re making wooden furniture, you might be concerned about splinters, and if you’re selling electronics, you might be worried about incorrect voltage. Start by thinking about your product’s specific characteristics and what types of defects might occur with it.

If you need inspiration and have sold the product before, you can reference customer complaints and return data. If you haven’t, you can try looking through customer reviews for competing products. You should also consider any issues that you had with your samples during the sampling process.

Some defects are more severe than others — a wood splinter can cause injury, so it’s more severe than a small scratch or dent. Once you have a list of potential defects, you should divide them into three categories: minor, major, and critical defects. For more information about defect classification, read this article.

Should You Rely on Your Third-Party QC Company to Develop Your Defect List?

If you’re hiring a third-party inspection company (like Insight Quality), you should certainly consult with them to get an idea of the most common defects they put onto their checklists for similar products. However, keep in mind that inspection providers will specialize in different product categories, so if you’re asking for advice, be sure they have the relevant experience.

Also, keep in mind that you are (or should be) the expert on the specifics of your product, and you should never entirely hand this responsibility off to your third-party QC company. The development of your checklist should be a collaborative process because, as the importer, you are the one who is ultimately responsible for quality management and your product quality standards.

Step 2: Arrange Your Quality Inspection Checklist into Sections

Your quality checklist will consist of different sections, and they should generally be similar to the ones in the following list. Depending on the type of product you have, you may not need to have all of these sections, or you may have more. The sections we typically include in our checklists are:

- Packaging & Labeling – Are shipping marks clear and legible, and are labels printed correctly? In this section, you will verify that your packages are not physically damaged in any way. Learn more about packaging quality control »

- Visual Inspection – What should the inspector check for visually as they hold or walk around the product? For example, when inspecting a doghouse, they might look for peeling paint or missing screws.

- Functional Testing – How should the inspector physically use or manipulate the product to ensure it works properly? For example, they might need to make sure the doghouse legs stand firmly without rocking and verify that accessories attach easily. Learn more about functional testing for the QC checklist »

- Physical Requirements – Do all product dimensions match specifications, is the product weight correct, and are all other physical requirements met? The inspector will use various QC inspection tools such as measuring tape and calipers to determine this.

- Special Tests – Based on your product’s unique attributes, you can create tests that are specific to it. For example, if your product requires assembly, you might need to verify that all the parts fit together correctly.

- Barcode Verification – Do all UPC labels match the purchase order information, and do they scan correctly? The inspector can use barcode readers to check this.

- Carton Drop Tests – In a carton drop test, your carton is dropped on the ground from different angles to ensure there is no damage to the product or packaging inside. This test simulates rough treatment that may occur during the overseas shipping journey. Learn more about carton drop tests »

Now that you have an idea of the sections that go into a quality inspection checklist, let’s look at an actual example

Is Your Quality Control in the Doghouse? Download This Product Inspection Checklist Template

Download this Sample Quality Control Checklist

To give you a concrete example, we’ve provided a sample quality inspection checklist for download. An inspector would use this checklist to conduct inspections on a wooden doghouse. Regardless of your product category, a lot of the information on this checklist is product agnostic. Use it for inspiration during the process of working on your own checklist.

3 Key Things to Understand About Product Quality Control Checklists

- This checklist is designed based on the AQL sampling methodology, which is an industry standard for consumer product inspections. For additional context, download our AQL Inspections 101 guide.

- Defect classification is an essential part of developing your checklist. To learn more about the differences between minor, major, and critical defects, read our article on AQL Defect Classification.

- If you want to hire Insight Quality Services to conduct inspections for you in China, Vietnam, or another manufacturing country, we can assist you with the checklist development process. To learn more about this service, visit our product inspection services page.

A Good Inspection Checklist Will Help Ensure Product Quality

If you want to ensure your products’ quality and avoid lousy product reviews and returns, a quality checklist is essential. It helps get you on the same page with your manufacturer and helps ensure products are made to your standards.

Use our doghouse checklist as a guide, and if you have any questions, leave a comment below or contact us directly.

Download this Sample Quality Control Checklist

Note: This article was originally published in February of 2018 and was updated in March of 2024.

AQL Inspections 101: How They are Conducted

Authors

14 comments

QA Kervin Singletion

The site was helpful.

Insight Team

Thank you for your support!

Nour

In case I conducted DUPRO inspection that includes functional, dimensional, and quality tests in addition to the packaging, is this enough?

it seems like everything required for the pre-shipment is covered in the DUPRO.

Insight Team

The need to conduct DURPO and/or Pre-Shipment inspections is different for each buyer and their objectives. DUPRO inspections take place during production and items are not generally completed and packaged.

Nour Mahmoud

Do I really have to print and fill out a pre-shipment inspection report every time a work order is finished? because the report is quite long.

and is it necessary to add pictures ? or consider workmanship?

can the long pre-shipment inspection report be sent once to the customer and then send a brief one

Insight Team

The frequency of inspections and the depth of information presented in the formal inspection report can be customized based on our client’s needs and requirements. While there are many categories of inspection points, workmanship is generally of high importance to our clients to ensure the quality of their products meets their standards. Whether to include photos and workmanship inspection points in the inspection and inspection report is the choice of the client, though one we would recommend.

Gillian

Hello,

May I know if you provide the service of checking the product quality of my purchasing baby milk bottle?

Insight Team

Yes, Insight has experience inspecting baby bottles. We are proud to be a member of JPMA, the Juvenile Products Manufacturers Association and have extensive inspection experience with juvenile products.

Scott

I noticed after the three defect classification columns of Critical, Major, and Minor there is a fourth one: Hold. How are these defects handled? I assume this classification means that the defect would not cause a shipment to fail, but instead be held for review by the customer. But you haven’t defined an AQL for this category. Does even one instance trigger a hold? Any clarification you could give would be helpful.

Insight

The “HOLD” result is generally used for non-quality issues such as packaging, labeling, etc and thus does not follow the accept/reject methodology of the AQL chart. The use of HOLDs is client specific and is something that you can customize based on your needs.

Terry

If I determine AQL based on variety of factor, should I must must included minor, major and Critical defect?

Insight

AQLs are determined for each defect classification. Generally Critical is 0. Major and Minor AQLs are based on a variety of factors but for most consumer products we start off with 2.5/4.0. You can conduct an inspection only using one of the levels.

Misganu

Where can I get AQL for pipes (DI, GI, HDPE, etc)?

Please help.

Insight

The use of AQL is not product specific. You determine the AQLs to use based on a variety of factors including risk and your desired level of quality. We have written several articles specific to AQL inspections and written an introductory to AQL inspections which you can download here https://insight-quality.com/aql-inspections-101/