It goes without saying that we live in a volatile and ever-changing world. Whether it’s the climate, an election, or a Super Bowl, plot twists are hidden around every corner (some are easier to see coming than others).

The volatility of our world applies to the manufacturing world as well, especially when you’re dealing with overseas factories. Having a product made internationally exponentially increases the things that can (and sometimes will) go wrong. A few examples are:

- Natural disasters

- Labor strikes

- Changes in technological capabilities

- Currency fluctuations or other economic crises

- A new tax or tariff

- Changes in regulations

- A coup or corruption in the government

And don’t forget – these points of failure aren’t limited to the country of origin. They can happen in the COO, the importing country (yours), or any country that the products pass through along the way.

This is why we recommend that our clients regularly evaluate their supply chains.

Are all of Your Eggs in one Basket?

You’ve probably heard the expression above – if you have 10 eggs and they are all in the same basket, they will all break if the basket falls or is smashed. Having a backup plan applies to tires on your car, financial planning, business, and most of general life. Even the US Navy Seals have a variation of the backup-plan principle: “Two is one and one is none.”

The supply chain is no different. We advise a “China + 1” strategy that ensures you have a second country/factory on call that can quickly pivot to address your production needs if something goes wrong. Having a second country of origin also includes additional set-up and transport considerations.

But what if you have a backup plan already? Taking a look at your supply chain is still beneficial when it comes to scaling your growth, lowering your bottom line, and increasing efficiency.

The following supply chain overview draws statistics from a recent global manufacturing report from Deloitte. A link to the full report is provided at the end of this article.

Supply Chain Part 1: Country of Origin

1. Labor & Materials

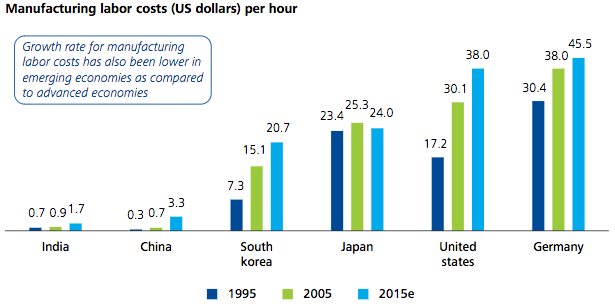

China is known as a competitive option for labor costs, but per-hour wages are rising.

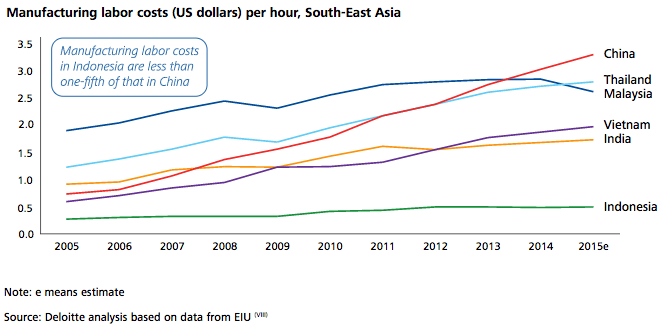

When compared with the “Mighty Five” manufacturing companies of Southeast Asia, China isn’t the low-cost labor solution that it once was, but there are many factors besides labor that play into overall costs and profitability.

Materials are another consideration. While Indonesia’s labor is less than one-fifth as expensive as China’s, it may be significantly more expensive to obtain the required materials for production in Indonesia, depending on your product line.

2. Transportation & Infrastructure

Transportation considerations include not only the shipment costs, but also any customs, duties, and brokerage service payments that are due at both the origin and destination.

The infrastructure of the country of origin needs to be examined, as well. The reliability of the infrastructure will directly affect the stability of your supply chain and the consistency of your shipments.

3. Seasonal Variances

Your country of origin may have seasonal variances that interfere with production. National holidays, climate patterns, or cultural differences may cause deal-breaking delays and setbacks that you need to be aware of.

4. General Costs of Doing Business

If you haven’t examined your COO’s general costs of doing business, it may surprise you how much they differ from surrounding countries that are equally viable. General costs of business include financing, insurance, banking fees, and other variables that are sometimes country-specific.

Examining your own costs while doing research on the costs for other countries will either reveal an advantage or an opportunity.

5. Ease of Communication

Communication isn’t usually a deal breaker at the country level but it still plays a role. Think about the stress and miscommunication that occur between English-speaking organizations. A language barrier amplifies these mishaps, so be sure to optimize for communication, if possible. Another option is to ensure that you have reliable contacts in the country (other than the factory) to help bridge the gap. For Chinese factories, Insight Quality offers responsive, reliable insight into what’s going on at your factories and can create fast solutions to the problems that arise.

In addition to language, consider the technological capabilities of the region. Will you be receiving communications by phone, email, fax, or snail mail? Speed and efficiency are essential when addressing issues or attempting a rapid turnaround.

6. Capabilities and Productivity

The materials, skill, and technological capabilities necessary to manufacture your product line will dictate what your COO options are. But beyond that, it pays to optimize your COO around the best intersection of capability and cost.

For example, Insight Quality works with a lot of companies that produce fashion jewelry. Because fashion jewelry is labor-intensive, it makes sense to seek a COO with cheaper labor costs (like China) even though there are other countries that could do the job just as well.

However, products that are made with plastic injection molding (low-labor) should be made in a country that has the best machinery available and can provide the best per-unit cost (after calculating other variables).

Check back later for part two of this discussion, where we’ll dive in to some supply chain considerations you can make after examining your country of origin.

Report cited: Deloitte, 2016 Global Manufacturing Competitiveness Index

0 Comments