Every time Chinese New Year (CNY) comes around, a new crop of importers gets thrown for a loop. Rookie buyers often fail to anticipate the holiday’s impact on their production timelines, shipping timelines, and quality control.

As many seasoned importers know, it’s critical to start planning for the CNY holiday far in advance. Factories shut down for several weeks, and after they reopen, it takes at least a few more weeks to get back up to full production capacity.

Here we discuss the typical effects of the holiday and the actions you should take to avoid problems in your business.

Table of Contents

When do Factories Close for Chinese New Year 2025?

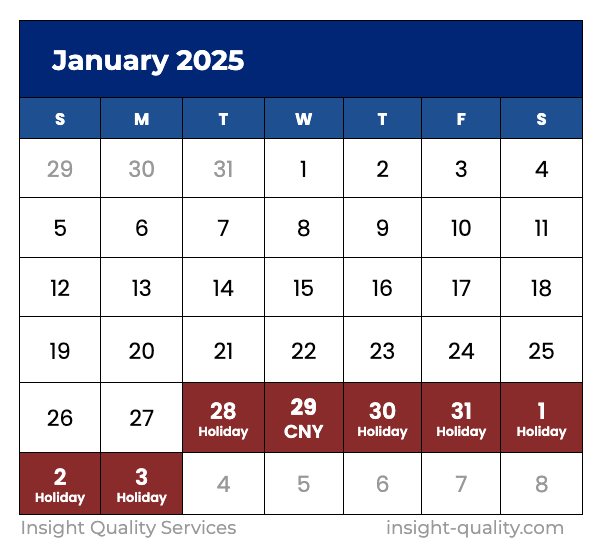

The dates for Chinese New Year and other traditional festivals are based on the Chinese lunisolar calendar, and thus they change every year, relative to the Gregorian calendar we use in the West.

January 29, 2025 is the first day of the “Year of the Snake.” The official government holiday will last from January 28th through the February 3rd. However, some factories will close earlier, and most will fully close for two to four weeks.

In the next three years, the first day of the new year will be celebrated on the following dates:

- February 17, 2026 – Year of the Horse

- February 6, 2027 – Year of the Sheep

- January 26, 2028 – Year of the Monkey

Be sure to check with your factory contacts to get their exact closure dates.

How Long do Factories Usually Shut Down for Chinese New Year?

During CNY, every factory in the country shuts down… Yes, every factory. The official public holiday only lasts for seven to eight days. But, most factories are fully closed for two to four weeks.

Additionally, many Chinese factory workers take extra time off, leaving in the weeks leading up to company closure dates, slowing production down significantly. Many workers will not return immediately afterward, meaning it can take up to a month for production to return to full capacity after the holiday.

Why do Factories and Employees Take So Much Time Off?

Chinese New Year, also called the Spring Festival, is the country’s most important holiday. Like Thanksgiving or Christmas in the US, people travel back home to spend time with their families.

Since most factory workers are migrant laborers, they generally live far away from their hometowns and travel hundreds of miles or more to return home. If they have a spouse and children, it may even be one of the only times they see them during the whole year.

Companies require long closure times to allow workers to travel home and then back to the city where they work. The 40 days of increased travel around CNY is referred to as Chūnyùn (春运), and this is the largest human migration in the world.

Chinese New Year Factory Shutdown: 5 Things You Need to Know

With so many people traveling for Chinese New Year and the lengthy factory closures, there are certain things you need to understand if you want to properly manage your inventory and maintain your expected level of quality.

#1 It Takes Factories at Least a Month to Ramp Back Up after CNY

You might assume that the same workers who left before the holiday will be coming back afterward. However, Chinese New Year is generally the preferred time to switch jobs in China.

Up to a third of workers might move to another factory or decide to stay in their hometowns and not come back. As such, your manufacturer needs to hire new workers and get them up to speed. Because of this, many factories will not be back to full production levels until about a month after CNY.

#2 There are Increased Quality Issues Before and After the Holiday

Before the holiday, factories are in a mad dash to get orders out the door, which leads to more things being missed and more quality issues than usual. After the holiday, the factory needs to hire new workers who are more likely to make mistakes than experienced ones.

As such, consider stepping up your product inspection efforts in the months before and after the Spring Festival. You can hire a reliable third-party inspection company like Insight Quality Services to help you do this.

#3 The Cost of Shipping Goes Up Drastically Around the Holiday

With the lengthy factory closures and the rush to get products out beforehand, manufacturers will often charge more if you want to ship an order close to CNY.

In addition to your factory taking time off, shipping companies also take time off. As such, heavy volumes are going to the ports before the holiday with only a limited number of ships, which means shipping rates go up.

Shipping rates have been a big topic in recent years, and they are much lower now than during the pandemic, but keep in mind that CNY is typically the most expensive time to ship.

#4 You Should Never Pay a Deposit Just Before the Spring Festival

Sometimes companies go out of business — and in China, the Spring Festival is the most common time of year to close down permanently. Factories that have not been doing well financially often choose to go out of business during CNY.

Paying a deposit just before the holiday can be a disastrous proposition. If your factory intends to close permanently and does not tell you, you may never get it back, so be sure to wait until they reopen.

#5 You Need to Forecast Far in Advance to Adjust for Production Times

As we’ve discussed, several factors affect production around the Chinese New Year. These include the rush before the holiday, the long closure times, and the ramp-up period afterward.

For any orders you would want to receive in March/April, you should start discussing them with your suppliers by around September/October.

When planning schedules, it is a good idea to take past data into account and also consider what may or may not happen globally. It is essential to forecast your inventory needs far in advance and consider many factors when developing your ordering schedule.

Some Other Chinese Holidays to be Aware Of

In addition to the Spring Festival, there are other holidays you should know about. In 2025, China will celebrate the following holidays with time off. While these holidays are not as significant, they do have some impact on shipments.

- New Year’s Day – Jan 1

- Qingming/Tomb Sweeping Festival – Apr 4

- Labor Day – May 1

- Dragon Boat Festival – May 31

- National Day – Oct 1

- Mid-Autumn Festival – Oct 6

Communicate with your factory before each holiday to determine which specific days they will be taking off.

Lunar New Year in Vietnam, Malaysia, South Korea, etc.

Aside from China, several other Asian countries where you may have manufacturing partners celebrate the Lunar New Year. These include Vietnam, South Korea, Singapore, and Indonesia.

While the Lunar New Year is an important holiday in these countries, the impact on production is less significant than in China. For example, the official holiday in Vietnam, called Tet, lasts from January 28 – February 3, and factories may take one or two weeks off.

This closure may impact production times, and quotations may be delayed. However, the delay is less significant than in China, where the impact can span more than a month.

Need Help Managing Product Quality Around CNY?

As we’ve discussed, Chinese New Year is China’s most important holiday, leading to significant factory downtime and increased quality mishaps. As such, you should step up your quality control efforts around this time.

Consider hiring a third-party product inspection company like Insight Quality Services to help you conduct inspections before your goods leave the factory. These inspections will help you ensure the quality of your products and avoid poor customer reviews and returns.

For more information about how to prepare for an inspection, we recommend reading the following guide.

Free Guide

How to Prepare for an Inspection

Are you thinking of hiring a third-party inspection company? If so, you need to be properly prepared. No one knows your product better than you do. So, make sure you give your service provider the information they need to ensure that your inspections are a success. Download this free guide to successfully preparing for your product inspections.

Please Note: This article was originally written in February of 2019 and has since been updated.

Nice article. But I really want to know about the scientific significance of Chinese zodiac.

Thank you for your comment. The significance of the Chinese zodiacs are beyond the scope of our articles but you may find this link beneficial: https://depts.washington.edu/triolive/quest/2007/TTQ07030/index.html

Thank for your the post. I was looking for chinese holiday calendar and got some important festival holidays here.

Thanks for this clearly produced information. I was aware that CNY is an important holiday but had not fully realized its impacts on ordering.

You have lots of great information here, but I would like to know more about what the standard time off for the Chinese factory workers is? is there a common standard for the amount of time off the workers are given and what the workers expect?

Thank you

The time off for Chinese New Year is not easily answered as there are many variables to take into account. The official holiday is a seven day observance but most factories close for two-four weeks.

Thank you so much! As I am new to ordering from manufactures directly this article was very helpful for me to plan .

We’re glad this was helpful for you! CNY is a vital consideration when working out an ordering schedule and quality plan.

Thanks for the good info, you’re spot on with our experiences.

Glad you concur! It is essential for importers to understand the holiday’s impact.

Thank you so much, for this great information. It has enlightened my knowledge about the right time to place orders

Good to hear, Moryam!

Thank you for this extremely useful information, exactly what I was looking for. In the process of starting my business/sourcing and wanted to know what to expect during the Lunar New Year!

Thank you for your comment, Courtney! Glad the article was helpful to you.

In the “do not pay a deposit” information you should probably mention that a 13th Month salary/wage bonus, that has become almost mandatory, is paid at this time of the year. This additional financial burden is another reason not to pay your own “bonus” in the form of a deposit at this time.

Thanks for sharing your thoughts, Darren. Yes, many factories pay a bonus for Chinese New Year, which is an extra cash outflow.

-Billy