How to Use the AQL Inspection Levels (General & Special)

To achieve optimal results in your quality inspections, you must grasp the concept of Acceptance Quality Limit (AQL) sampling, particularly the inspection levels. A thorough understanding of inspection levels empowers you to interpret your inspection results accurately, reducing the risk of goods falling short of your standards.

When you refer to the AQL chart, you’ll encounter two types of inspection levels—General and Special. Understanding the distinct roles of the General and Special Inspection Levels equips you with the knowledge to make informed decisions about your inspections.

Let’s explore how they influence your inspection and how to utilize them effectively, instilling the confidence to excel in your quality control efforts.

Table of Contents

What are the AQL General Inspection Levels?

When conducting an AQL sampling inspection, we use the General Inspection Levels to determine your overall sample size. For instance, if you ordered 3,000 units from your factory, it might determine that we would inspect 125 units.

When used in conjunction with AQL levels, your inspection level plays a role in determining the number of acceptable defects. For instance, ten or fewer minor defects might be deemed acceptable during your inspection, while 11 or more would trigger a failed inspection. Understanding this prepares you to interpret your inspection results.

There are three General Levels (I, II, and III):

- General I is the most cost-efficient level because it gives you the smallest sample size and allows you to inspect the fewest products. However, it provides the least confidence in the inspection results.

- General II is considered the ‘normal’ or ‘default’ inspection level. It is the most commonly used by consumer product importers.

- General III is the most stringent and provides the most confidence in your inspection. However, it may increase inspection costs because you will inspect more pieces.

Now, let’s walk through an example of how to use the General Levels to determine your sample size.

How to Use the General Inspection Levels

Suppose you’ve ordered 1,300 USB hubs from a factory in Shenzhen, China, and want to inspect them before they ship. You decide to use General II because it is the most commonly used or ‘default’ inspection level. How do you determine how many units the inspector should check?

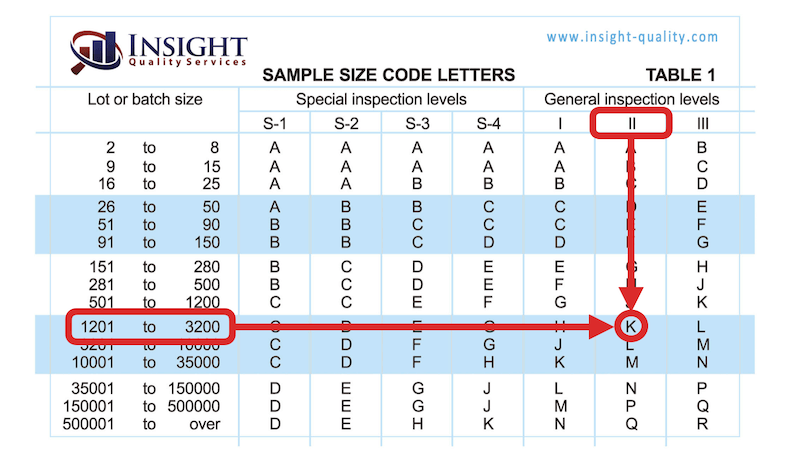

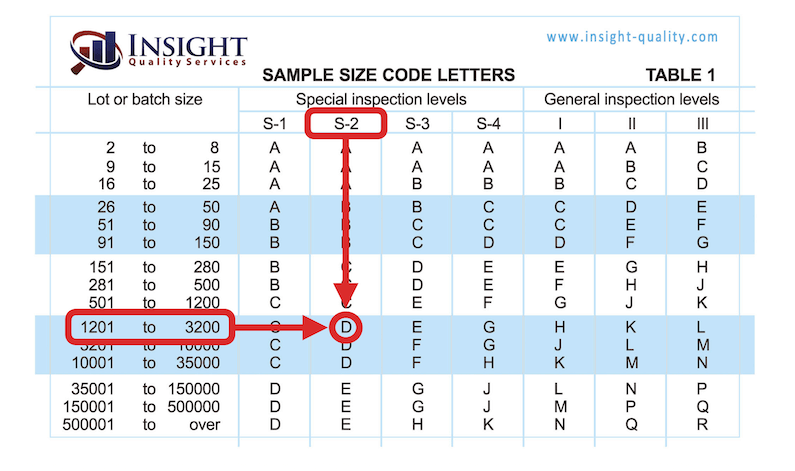

Let’s take a look at Table 1 of the AQL chart. With an order quantity of 1,300, your ‘Lot or batch size’ falls between 1,201 and 3,200, which you can see in the left column. We find General II at the top right and look at the point where the row and column intersect. Doing this gives us a Sample Size Code Letter of ‘K.’

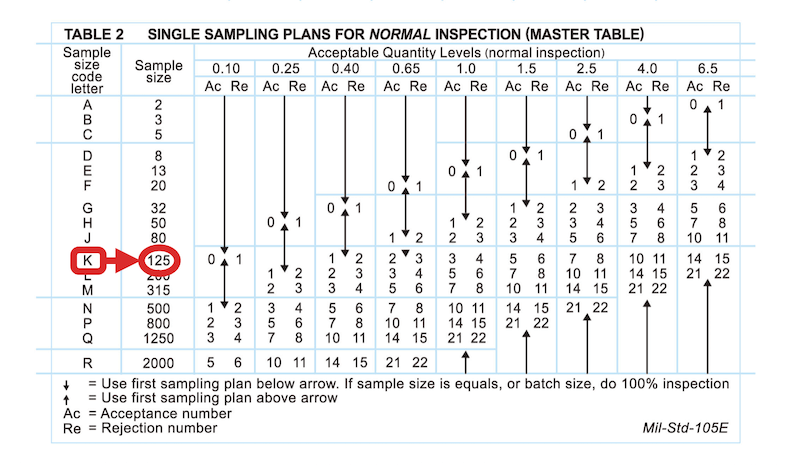

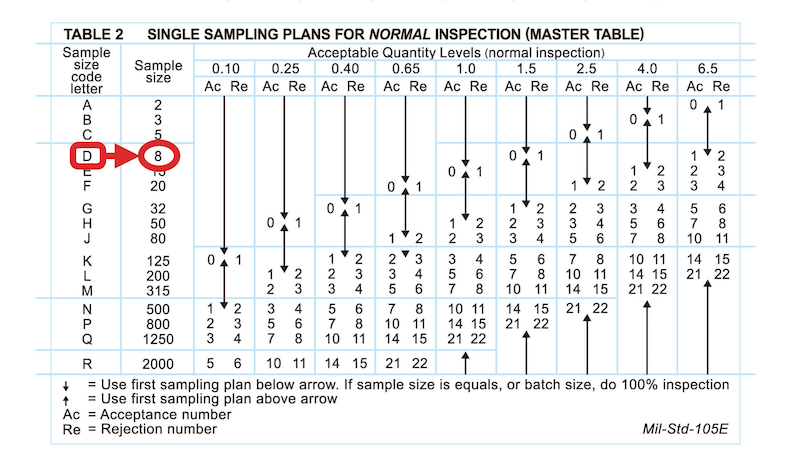

We then jump down to AQL Table 2 and find ‘K’ in the column on the left. In the next column, we see that your sample size is 125. That means when the inspector goes to the factory, they will pull 125 random USB hubs from your cartons for inspection.

The example above assumes we are using General Inspection Level II — but what if we had chosen a different inspection level?

- If we had chosen General I, our code letter would be ‘H,’ and the inspector would check 50 units. You’d have a smaller sample size, leading to less confidence in the inspection result but potentially lowering inspection costs.

- If we had chosen General III, we would be inspecting 200 hubs. You’d have a larger sample size, increasing confidence in the result but potentially increasing inspection costs.

So, choosing a different level would directly impact the sample size and the inspection process. This awareness is critical to making informed decisions and ensuring the quality of your products.

What are the AQL Special Inspection Levels?

During your inspection, the inspector will check various attributes of your product and packaging based on the items on your quality inspection checklist. For many checks, such as visual inspection and measurements, completing them within a short time frame is possible.

However, some tests, like verifying functionality, might be challenging to complete within a standard inspection time frame. So, we use the Special Inspection Levels (S-1, S-2, S-3, and S-4) to create a smaller sample size for those specific tests.

Like the General Levels, selecting the lowest level (S-1) will give you the smallest sample size. Thus, it will lead to less confidence in the result and lower inspection costs. On the other hand, selecting the highest level (S-4) will give you the largest sample size, with the most confidence, but at the highest cost.

At Insight Quality, we typically think of S-2 as the ‘default’ Special Inspection Level. You can use that as your starting point, then adjust it up or down depending on factors like:

- The risk level for the item

- Complexity of the item

- Type of test being conducted

- Desired inspection cost

- High-end vs. low-end product

- The price point of the item

- New item vs. established item

- New technology vs. existing technology

Now, let’s walk through an example of how you would use the Special Levels to determine your sample size.

How to Use the Special Inspection Levels

Let’s say we’ve ordered 1,300 USB hubs and are checking 125 of them based on our General Level. However, we need to conduct a function test to plug a device into each USB port to ensure it charges. It’s unrealistic to do this for all 125 hubs within a reasonable time frame, so we use a Special Inspection Level, the standard level of S-2, for the test.

We look at Table 1 of the AQL chart and find 1,201 to 3,200 in the left column since our order size falls within that range. Then, we look at S-2 under Special Inspection Levels at the top of the table. We see where they intersect and find the code letter ‘D.’

Now, we go to Table 2, find our code letter ‘D’ in the left column, and see that this gives us a sample size of 8. So, for our function test, we’ll set aside eight hubs and plug a device into each USB port to ensure it charges.

What if we had chosen a different Special Inspection Level? If we had chosen:

- S-1, we’d test 5 hubs.

- S-3, we’d test 13 hubs.

- S-4, we’d test 32 hubs.

As mentioned above, you might consider changing your Special Inspection Level for various reasons, but S-2 is the ‘default’ level for this type of test.

Hopefully, you now have a better understanding of the AQL Inspection Levels. If you have any questions, feel free to ask in the comment section below.

Need Help Inspecting Your Products? Insight Quality is Your Reliable Inspection Partner

At Insight Quality Services, we use AQL sampling to help our clients inspect products on-site at the factory in countries worldwide. We can go to the manufacturing site on your behalf to verify that suppliers are meeting your requirements.

Contact us to learn about our product inspection services and request a quote from our team. You can also download our free AQL 101 guide using the link below.

Nice clear explanation, top work.

Glad you found it helpful!

very good definition with a suitable example.

Thank you very much

Glad you found it helpful!