5 Ways to Ensure Product Quality and Make Your Customers Happy

Table of Contents

Low prices might make your customers happy in the moment, but quality products are what keep them coming back for more. In this article, we’ll share five of the top ways to boost your product quality in manufacturing and ensure your consumers are always thrilled.

#1: Focus on Design

Producing a high-quality product starts long before questions of manufacturing or inspection come into play. From conception to consumption, a high-quality product is only as good as its design.

Products must be designed to serve the consumer’s needs and solve the consumer’s problems. Ask yourself: How can I make my product more efficient? More effective? What are the best materials to use in order to achieve the desired result?

A well-designed product is easy to use, effective, and long-lasting. By designing your product with a particular audience in mind, you can make sure customer satisfaction stays high. More satisfied customers means more repeat sales, more good reviews, and more referrals.

Learn More: How Does Product Quality Affect Customer Satisfaction?

#2: Specify, Specify, Specify

While inspecting your products is important, good quality can’t be added on after the fact. You need to be extremely specific as to what you want your product to be before the manufacturing process begins.

To this end, creating a thorough product specification sheet is crucial.

A comprehensive product specification sheet should outline all essential requirements for the manufacture of your product. This will include exactly what you want in terms of materials, volume, size, shape, weight, measurements, packaging details, and testing and inspection requirements. Everything you want your manufacturer to produce and to what standard it should be produced must be included.

Inexperienced buyers may think that they can trust their supplier to make decisions about how to make their product. That may work for certain manufacturer relationships, but it’s much safer to know exactly what goes into your product and to be as specific as possible about how you’d like it made. “High-quality aluminum” might be up for interpretation, but “aluminum alloy 6063-T5” is not.

Learn More: What are Product Specifications, and Why are They Essential for Quality Management?

#3: Audit Your Factories

Once you’ve designed your product perfectly and specified exactly how you want it made, you can move on to the manufacturing process. When deciding which manufacturer to use, it’s essential to audit your factory.

A standard factory audit involves sending an auditor to assess a manufacturer’s facilities before you commit to buying from them. Auditors can observe and record any number of factory competencies, including:

- Capability: Is the factory able to manufacture your goods on your timeline?

- Quality: Does the supplier have a solid quality management system in place?

- Security: Is the manufacturer complying with U.S. Customs and Border Protection’s C-TPAT program?

- Social Compliance: Are working conditions good?

- Environmental: Is the factory complying with environmental standards?

Factory audits are invaluable when making your decision about which manufacturer to choose, but you should also continue to audit your factory regularly after committing to one. This ensures quality won’t slide over time.

Learn More: What is a Factory Audit, and is it Different From an Inspection?

#4: Develop a Quality Control Plan

Things can’t go to plan if you don’t have one! Developing a clear and consistent quality control plan is important for ensuring your products meet your quality standards.

Good quality control plans outline a variety of policies. Ask yourself:

- What are my goals and objectives?

- What steps and procedures should I have in place to achieve those objectives?

- What is the best way to allocate responsibility at my company?

- What specific quality standards should we be meeting?

- What testing, inspection, and auditing programs will ensure our products are high quality?

- How can we assess if we are succeeding at our goals? How can we modify our plan if we are not?

Having explicit policies for how to achieve your quality control goals sets you up for success.

Learn More: How to Develop a Simple Quality Control Plan for Your Product

#5: Inspect Your Products Regularly

Well-thought-out prep work is vital, but it’s equally important to inspect your products regularly to make sure nothing is slipping through the cracks.

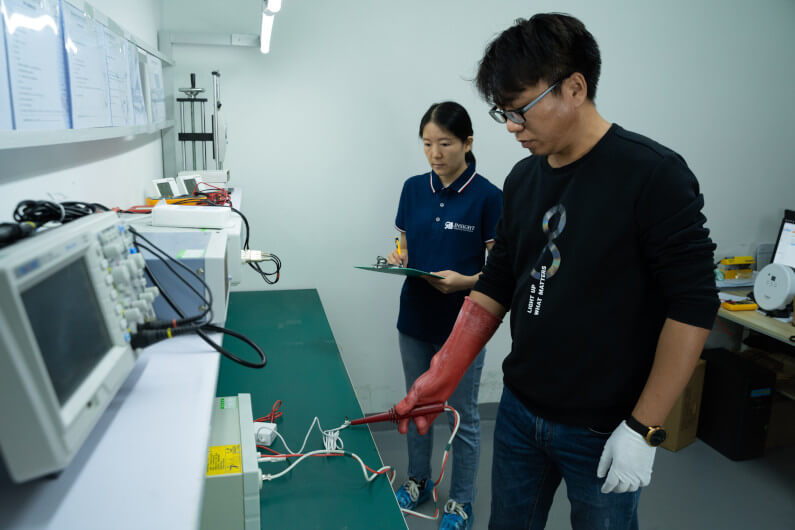

You should have in-house or third-party quality inspectors working on your team. These inspectors go to factories and pull random samples of products to make sure they are up to standard. They check packaging, labeling, physical requirements, and anything else relevant to quality.

You’ll then receive a quality inspection report so you know exactly what’s going on in your manufacturing process. This will let you make the best decisions for your products moving forward.

Learn More: What is a Product Quality Inspection, and How Do They Work?

Insight Quality Services Helps You Ensure Product Quality

At Insight Quality Services, we offer a wide range of services to ensure your products are manufactured with the consistency and quality your customers expect.

Schedule a consultation with us today to discuss your auditing or inspection needs. You can also learn more about the relationship between price and quality by downloading our free guide.

Price vs. Quality: Your Free Guide

Importing goods from overseas makes sense for many importers due to the low costs of production. However, this doesn’t matter much if you receive low-quality goods that you can’t sell to your customers. It is essential to take all the necessary steps to balance price and quality. Our free Price vs. Quality Guide gives deeper insight into how to navigate these waters.

AQL Inspections 101: How They are Conducted

Authors

2 comments

IDEWA VICTOR ERNEST

I loved reading it

Insight Team

Thank you for your feedback. We hope it is helpful.

Comments are closed.