How to Write a Purchase Order That Protects Your Interests

Table of Contents

Failure to set expectations with suppliers is something that often comes back to bite importers, especially newer ones, hard. Missed shipping dates, inaccurate quantities, misunderstood payment terms–these are all things that can be avoided by setting the right expectations from the beginning.

How do you set expectations when placing an order with a factory in China, Vietnam, Malaysia, or another offshore sourcing destination? One of the most important things you can do is to send your supplier a clear and detailed purchase order, or PO.

What is a PO?

A purchase order is a document that you create, and it represents your formal offer to the supplier, dictating terms and providing all the information they need to handle your order. A good purchase order leaves no ambiguity–as too much ambiguity gives the supplier room to fill in the blanks with their own ideas and ship you an order that doesn’t meet your expectations.

What should be included in your Southeast Asia or China PO?

The Bare Minimum You Need to Have in Your Purchase Order

Your purchase order will generally be a PDF or Excel file, and there are certain basics that every PO needs to have, including the following:

PO Number and Date

Assigning a number and date to each purchase order helps with tracking and gives you something to reference when discussing orders with your supplier.

Buyer’s Name, Address, and Contact Info

It is important that all contact information is available, should the vendor need to contact you, and it also helps with processing.

Supplier’s Name and Address

This is helpful for clarity, as well as for your own reference.

Ship To Address

If your ship-to address is different from the buyer address, you can list it separately.

Item Quantities

Specify the quantity requested for each item to help facilitate the purchasing process.

Item Names

Provide any item numbers, names, and basic descriptions available for all of the items in your order.

Item Prices

Include the unit price you have discussed with your supplier, as well as the extended price (no. of units x price per unit) for each item, and a total. In addition to these basic elements, your purchase order can be improved by adding more details to help you protect your interests and ensure a smooth ordering and shipment process.

Additional Items That Will Make Your PO More Robust

Aside from details like contact information, quantities, and price, you can also consider the following:

Shipping Dates

List the date you expect the order to be shipped as well as the expected delivery date.

Shipping Method

This is often labeled with the heading “ship via.” Under this heading, you can indicate the specific name of your freight forwarder, or you can simply say “ocean freight.”

Item and Carton Weight

Incorrect carton weight is one of the biggest reasons for customs delays. In order to avoid such delays, it helps to specify the weight of each item, as well as the weight of each carton.

Product Specifications

Including product specifications as an addendum to your purchase order helps to confirm that the supplier is aware of them. Specifications can include things like size, measurements, components, materials and anything else of importance. In addition, if you have a Bill of Materials (BOM) list, you should include that as well.

Terms and Conditions

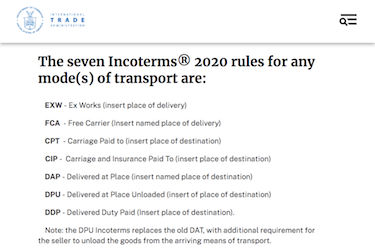

Include any payment terms (i.e. 30% on deposit, Net 70% after copy of B/L, Invoice, & Packing List). You can also include relevant Incoterms and any other terms of the order.

Communication Records

You can include screenshots of any emails that were sent to you by the supplier, such as the emails in which they sent quotes to you.

Carton Packing & Container Loading Instructions

You can include diagrams illustrating how your master cartons should be packed and the number of items per carton. You can also include diagrams illustrating how the cartons should be loaded onto pallets and/or into the container for space maximization.

Third-Party QC

Set expectations for any third-party inspections that will be conducted either before, during, or after production.

Adding any of the items above will help enhance clarity with your manufacturer and help protect your interests as an importer. Just be sure that you are only adding things that you have previously discussed with your supplier. You need to be extra sure that they understand and are aware of everything.

Conclusion

Setting expectations with your suppliers helps minimize risk and get better overall results. Creating a proper purchase order helps you to accomplish this.

When creating a purchase order, you should always be sure to include the basics like a PO number, item quantities, and prices. But you should also consider including more details such as shipping dates, product specifications, and third-party QC plans. Doing so enhances clarity and reduces ambiguity between the buyer and seller.

If you are working with a new factory and want to learn more about how to conduct a product inspection, we recommend downloading the following guide.

Free Guide

How to Prepare for an Inspection

Are you thinking of hiring a third-party inspection company? If so, you need to be properly prepared. No one knows your product better than you do. So, make sure you give your service provider the information they need to ensure that your inspections are a success. Download this free guide to successfully preparing for your product inspections.

AQL Inspections 101: How They are Conducted

Authors