AQL sampling is an industry-standard method for consumer product inspections. It determines how many units the inspector should check and how many defects are allowable.

Once you’re face-to-face with an AQL chart or calculator, it’s time to decide on your AQL and inspection levels. If this is your first time conducting inspections or you are considering changing your AQL levels, you may be unsure about what to choose.

Here, we discuss some ideas to help you make the right decisions for your unique situation.

Table of Contents

Start With the Default AQL and Inspection Levels

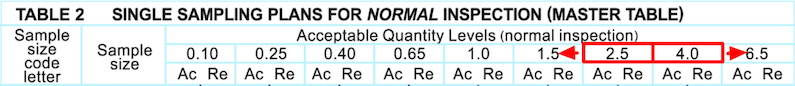

For consumer products like stationery, pillows, furniture, toys, and electronics, the most common recommendation is as follows:

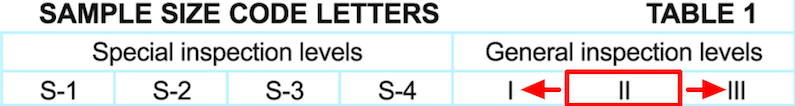

Inspection Level: General II

AQL Levels: Critical Defects: 0, Major Defects: 2.5, Minor Defects: 4.0

You’ll note that each type of defect has it’s own AQL level. By making these selections, you are deciding that, over the course of many inspections, these defect percentages are the maximum you’re willing to accept.

Keep in mind, though, that during your inspection certain tests may be assigned a different AQL level. For the ones that are destructive, expensive, time-consuming, or tend to yield the same results, you’ll use the special inspection levels.

So, why might you choose different AQL levels, other than the default selections?

Adjusting Your AQL Levels Based on the Product and Market

Higher-end brands might want to adopt stricter standards for quality. For example, instead of 0/2.5/4 defect levels, it might be appropriate to choose 0/1.5/4. Whereas a lower-end brand might be more tolerant of defects, opting for 0/4/6.5.

To make this choice, consider your own brand and market, and think about what your consumers are willing to accept.

There is no one right answer for all situations, so it’s important to consider your product and market and what’s acceptable to you. But the standard recommendations tend to work for most consumer products.

These considerations apply to your AQL levels, but what about your inspection levels? When you’re thinking about inspection levels, you should consider your relationship with the factory.

Adjusting Your Inspection Levels Based on the Factory’s History

When you lower your inspection levels, fewer units get inspected, which reduces the amount of confidence you can have in the inspection — but it also might lower your inspection costs. Raising your inspection levels, on the other hand, has the opposite effect.

As we’ve said, General II is the most common inspection level. But if you have a long history with your factory, you might consider dropping down to General I. It’s only a good idea to lower your inspection level once a supplier has earned your trust and produced consistent results. If you find that the results start to slip, you could go back up to GII until things improve.

If, on the other hand, you’re working with a new supplier or having quality issues with a long-term partner, adjusting to GIII will give you a larger sample size. And this way you can have higher confidence in the inspection result. Once your results with the supplier start to improve, you can revert to GII.

With that said, let’s recap and discuss some final thoughts about inspection costs.

Summary and Final Thoughts

Most inspections for consumer products are conducted at the General II inspection level with AQL levels of 0 for critical, 2.5 for major, and 4.0 for minor defects.

- You can consider changing your AQL levels based on your product and market. Lower AQL levels might be appropriate for higher-end products and higher AQL levels might be appropriate for lower-end products.

- Consider changing your inspection levels based on your history with the factory. You might consider going to General I with high-performing factories or switching to General III with new or low-performing ones.

Lowering your inspection levels might help you to lower your quality control spend. Another way to reduce inspection costs is to conduct skip lot inspections.

Keep in mind, though, that when you’re considering actions to reduce inspection costs, you should only make decisions that are based on objective data. For more information about how to do this, you can read our article on maximizing your quality spend.

Learn more about our quality inspection services. Or, for a high-level overview of AQL, download the following guide.

Good and relevant information.

Thankyou for this 😊.

We’re glad it was helpful!