Product quality is a vital concern for importers today. Great marketing and distribution mean nothing if your products aren’t up to customer standards. And when quality control practices slip, it can lead to a dangerous snowball effect of bad reviews, excessive returns, lost customers, and decreased revenue.

That’s why understanding quality control is vital to the success of your business.

In this article, we’ll give you an expert-level rundown of quality control—inspections, lab testing, and best practices—to help you keep your product quality high and your company thriving.

Table of Contents

What is Quality Control?

Quality Control (QC) consists of the actions taken to ensure that the quality of manufactured products is high, consistent, and up to predetermined standards. These measures aim to identify errors and verify that products adhere to specific product criteria. They are important because, ultimately, they enable you to please your customers. Great quality control also provides essential feedback that can help you drive continuous improvement in your manufacturing processes.

As defined in ISO 9000, Quality Control is a subcategory of Quality Assurance (QA). It typically involves the following processes and considerations:

Quality Inspections

A quality inspection is the process of checking your products to ensure that they meet predetermined standards. Quality inspections let you confirm that your manufacturer is making the products correctly, and if the supplier is overseas, a third-party inspection company can go to your factory to conduct the inspections on your behalf.

The steps involved in a standard quality inspection are:

- An inspector travels to your manufacturing facility.

- The inspector pulls random samples of your product (see “What is AQL Sampling?” below).

- The inspector runs tests and evaluates the sampled product based on the inspection checklist you have developed with them. This checklist can include specifications about the product itself, packaging, labeling, and more.

- The inspector compiles an inspection report, which includes notes, pictures of your product, and tells you whether or not the goods passed inspection.

Importers usually conduct quality inspections after the manufacturer has finished producing the goods but before they have shipped. However, you can schedule your inspection whenever it best serves your needs, at any point during the manufacturing process.

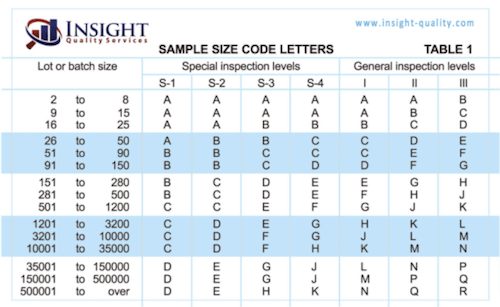

What is AQL Sampling?

Acceptance Quality Limit (AQL) sampling is a statistical method for sampling your product to ensure high quality. This method helps determine how many products are pulled for inspection. It also determines how many (and what level of) defects are allowed in an approved shipment. You can use this AQL chart to determine the ideal sample size and the number of allowable defects per order.

Essentially, AQL sampling determines the lowest tolerable quality level of your goods.

What are the benefits of AQL sampling?

![]()

For newer importers who care about quality, there’s an expensive fallacy that goes, “If inspecting x% of my shipment is good, wouldn’t inspecting 100% of the products be even better?” While this is reasonable for low-volume orders of goods, it becomes less and less possible as your order quantities increase. The more goods you order, the more time an inspection will take—and the more it will cost.

AQL is a time- and cost-effective inspection sampling formula. It’s a flexible procedure that uses proven statistical modeling and leads to fewer product defects. And while the typical level of allowable product defects is 2.5%, you can always set your AQL at 1% and put yourself ahead of the curve. Learn more about how to choose the right AQL level.

How Often Should You Inspect?

No matter how detailed your quality standards, inspections won’t do much unless you conduct them at a sensible frequency. Choosing how often you inspect your goods is a critical decision.

Many importers conduct inspections before, during, or after production to maintain high-quality products. However, frequent inspections are costly. It’s important to determine a frequency of inspection that works within your budget while leaving time to take corrective actions, if necessary.

What factors help determine inspection frequency?

![]()

First, consider your supplier. Is this a new supplier or one you have a history with? When you’re getting to know a new supplier, it’s wise to conduct additional inspections to ensure their practices are up to your standards.

With suppliers you know and trust, fewer inspections may be necessary. However, do continue to conduct inspections, even if infrequently. Quality fade—a gradual decline in product quality—often occurs overseas. Checking your manufacturers’ work is always a good idea.

It’s also best practice to consider your particular product and its use when determining inspection frequency. Are you manufacturing a high-end product that discerning consumers may find fault with? Or are you importing a lower-value product? Is your product vital (such as a medical device)? You’ll want to conduct more frequent inspections for high-end or high-risk products. Learn more about how to pick a quality inspection frequency.

What is Lab Testing?

Lab testing is a quality control measure you can conduct at any stage in production. Samples are sent to a lab where technicians use specialized equipment to assess their adherence to certain standards.

While inspections are important for quality control, they can’t catch every specific issue in a product. For example, only through specialized lab testing can you ascertain if a product has high levels of a potentially hazardous chemical—this isn’t something an inspector can assess just by looking at it.

Lab testing is often essential to ensure regulatory compliance and may be required for your product. For example, if you import children’s products into the United States, you must test them to comply with CPSIA regulations.

When selecting a testing lab to work with, check that they are properly accredited. Labs with ISO 17025 certification or those on the CPSC-Accepted Testing Laboratories list will be well-equipped to follow proper testing procedures. Learn more about the basics of lab testing.

Insight Quality Services Helps You Ensure Great Quality

![]()

Insight Quality services can help you conduct thorough product inspections to ensure your products are (and stay!) high quality. We can also help you lab test your products to ensure regulatory compliance.

Contact Insight to schedule a consultation today, or download our free guide to seven things all importers need to know about third-party quality inspections.

Third-Party Inspections: 7 Things You Must Know

When hiring manufacturers in developing countries, it is difficult to manage product quality.

Working with a third-party inspection company like ours helps you to ensure product safety, minimize returns, and maintain your good brand image. But there are certain things you need to understand to really leverage the service and get the best results.

Find out what they are in this guide.

0 Comments