Are you manufacturing consumer products at a factory abroad? Ensuring they’re well-made is essential to your success. A product that breaks easily or doesn’t meet customer expectations can lead to returns, negative reviews, and a damaged brand reputation. Quality inspections help you avoid these issues.

A quality inspection is a process that involves checking various attributes of a product and testing it against pre-defined standards to determine conformity. The factory’s quality control team, the buyer, or a third-party inspection company can conduct the inspection.

Many importers rely on third-party inspectors to check their products before the factory ships them. Doing this helps verify they meet quality standards, which helps protect their brand and ensures customer satisfaction. Here, we’ll cover how a quality inspection works and what you need to know to conduct one effectively.

Table of Contents

What are the Steps Involved in a Quality Inspection?

At Insight Quality Services, we conduct many inspections following a straightforward process:

- Travel to the Facility and Pull Random Samples

The inspector travels to the factory and selects a random sample of products for inspection, typically following the AQL sampling method (explained below). - Complete Checks From the Inspection Checklist

With the samples collected, the inspector goes through every item on your inspection checklist. This includes checking packaging and labeling, visual inspection, verifying physical requirements, and more. - Compile and Send the Inspection Report

Once all checklist items are reviewed, the inspector prepares an inspection report. This report includes a Pass or Fail result, photos, and any relevant notes about your products.

So, when should a shipment be inspected for quality? Most inspections take place after a production run is completed and before shipping. However, inspections can also be conducted before or during production, depending on your needs. In the sections below, we’ll provide more detail.

How Does The Sampling Process Work?

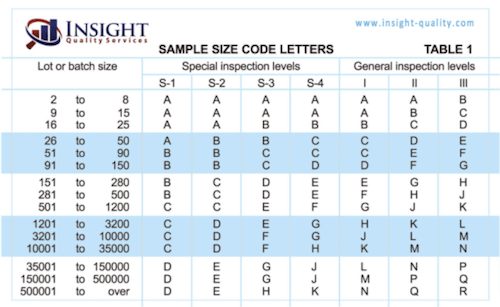

Sampling is essential to product quality inspections because it lets you get a clear picture of how well a lot conforms without examining every item. Rather than inspecting each piece in a large shipment, you can conduct a quality inspection using a random sampling method that reflects overall production standards. The industry-standard process is called AQL sampling.

Defects are classified into three categories: minor, major, and critical. Before beginning an inspection, you establish acceptable defect levels for each type. This approach ensures that your inspection criteria are aligned with your product quality goals.

Using these predetermined criteria, the inspector selects a sample size based on standard statistical guidelines, checking for the specified number of allowable defects. By focusing on a representative sample, you save time and resources while making informed decisions about your shipment’s quality.

For more details, you can download our in-depth AQL 101 guide to help you understand inspection sampling.

How Do You Create an Inspection Checklist?

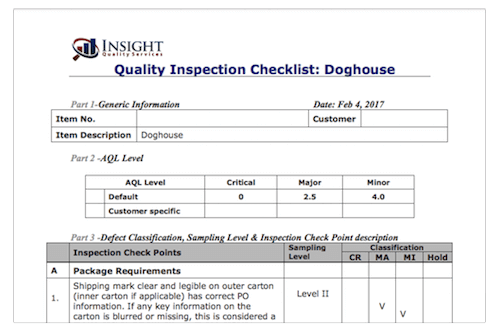

A checklist is essential for every quality inspection — it guides the inspector through each test and check they need to perform, covering aspects like packaging, labeling, functional testing, and physical requirements.

If you’re working with Insight Quality or another inspection service provider, it’s important to collaborate with the inspection team to create your checklist. While we offer standard checklists based on our experience, your input is crucial since you have the deepest understanding of your products.

Ultimately, it’s your responsibility as the buyer to ensure the checklist includes all critical quality aspects for your products. Be sure to put careful thought into this document, as it reflects the standards you and your customers expect. For a detailed example, check out our article on creating an inspection checklist.

What is in Your Inspection Report?

After the inspection, you’ll receive a report with a Pass, Fail, or Hold result for your shipment, along with detailed findings from the inspection process.

The report includes the outcome of each check performed, complete with photos of each step, so you have a clear view of your product’s condition.

It’s essential to review your inspection report thoroughly, whether the result is a Pass or a Fail. If any issues are identified, you’ll need to work with your supplier to determine corrective actions. For a closer look at what’s included in an inspection report, download our sample inspection report.

What are the 4 Types of Quality Inspection?

Importers use four main types of inspections to ensure product quality:

- Pre-Production Inspections: Conducted before production starts, these inspections can help verify the quality of raw materials or factory readiness.

- During Production Inspections: Conducted while production is still underway, these inspections can help you catch defects early and reduce delays.

- Pre-Shipment Inspections: The most common type of inspection, they are conducted once your goods are 100% produced and at least 80% packaged.

- Container Loading Inspections: Conducted while the goods are being loaded into a container, they help you to supervise the loading process.

While many importers opt for an inspection at the end of production, allowing them to confirm the quality of finished goods before they’re shipped overseas, each inspection type serves a unique purpose and offers specific benefits. Some clients choose to conduct all four types of inspections at different stages in the manufacturing process, while others rely solely on pre-shipment inspections.

To learn more about each inspection type and its advantages, check out our article on the types of inspection.

Quality Inspection vs. Quality Control

You may wonder about the difference between quality inspection and quality control. People sometimes use these terms interchangeably and even use terms like ‘quality control inspection’, but there is a distinct difference between these terms.

Quality inspection involves verifying the characteristics of your products to ensure they meet specific standards. This process can be conducted by factories, buyers, or third-party inspectors, verifying adherence to set requirements.

Quality control (QC) is a broader system focused on maintaining product quality. It includes various activities, such as inspections and lab testing, to confirm products meet safety and compliance standards.

While quality inspections are part of quality control, QC encompasses all measures to ensure product conformity. Together, they help companies achieve consistency and reliability in their offerings. To learn more, check out our article about quality inspection versus quality control.

Summary

By now, you should have an idea of how a quality inspection works for consumer products. If you want to ensure product quality, these inspections are a valuable tool to help you manage your supply chain and ensure good business outcomes.

If you’d like to learn more about our product inspection services, please reach out to us. And if you want to know how to prepare for a quality inspection, we recommend downloading the following guide.

Free Guide: How to Prepare for an Inspection

Are you thinking of hiring a third-party inspection company? If so, you need to be properly prepared. No one knows your product better than you do. So, make sure you give your service provider the information they need to ensure that your inspections are a success.

Download this free guide to successfully preparing for your product inspections.

Note: This article was originally published in March of 2019 and has since been updated.

wow…just what i was looking for! well explained and detailed…never knew quality control was this vast…thanks for this info.

Thank you for the feedback!

Thank you for sharing this.

We’re glad you found it helpful, Julieta!

-Billy Miner